What is a Turnbuckle and How Does it Work?

Turnbuckles, also known as rigging screw or tension devices, are a widely used type of rigging hardware used to adjust the slack or length of wire ropes, electric wolves, tie rods, and other tension systems. Turnbuckles consist of three main components: a body, a right-hand threaded end fitting, and a left-hand threaded end fitting. The two fittings are screwed into the ends of a small metal frame, one with a left-hand thread and the other with a right-hand thread. The tension is adjusted by rotating the frame, which can screw in or out of both fittings at the same time without twisting the attached cables.

Table of Contents

What Are Turnbuckles Used For ?

As a connection point, turnbuckles are often used with ropes, cables, or other rigging components, and their applications are very wide. Common turnbuckle applications include:

Sports and entertainment – turnbuckles are used as fixing points to create tension in the ropes around wrestling or boxing rings.

Construction – commonly used to provide tension support for suspension bridges, large buildings and highway guardrail cable assemblies, such as fences, gate shade sails and other outdoor applications.

Marine – Turnbuckles are commonly used to tension lashing and rigging assemblies for ships.

Automotive Aerospace – Suspension systems for the automotive industry and aircraft control systems for the aerospace industry.

Part Of A Turnbuckle

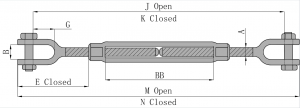

Body: The main metal frame that connects the two threaded end fittings is called the turnbuckle body. The end fittings can be extended and retracted and tension adjusted by rotating the body. There are two types of turnbuckle bodies: open and closed. Open turnbuckles have visible threads on the frame and are more traditional turnbuckles. Closed turnbuckles (or tubular bodies) enclose the threads in a closed frame and have a slim profile to fit into tighter spaces.

Nut: Also known as a lock nut, it is a small piece of hardware that can be screwed onto the end fitting of a turnbuckle. Once tightened, it can be tightened against the turnbuckle body to provide additional security and prevent the device from loosening or falling off. This is especially important in work environments with vibration or movement that can easily cause the nut to loosen.

End fittings: These are the connection points that screw into the ends of the turnbuckle body. One end fitting has a right-hand thread and the other has a left-hand thread. This left-hand and right-hand thread design makes it easy to adjust the tension after installation without moving the end fittings. Turnbuckle end fittings can be mixed and matched, and we can also customize a variety of end parts.

There are three common and popular end fittings:

Hook turnbuckles: Hook-end fittings are easy to connect and disconnect quickly, making them a convenient choice for making temporary connections.

Eye turnbuckles: Eye-end fittings are solid rings that provide a permanent connection without weak points.

Jaw turnbuckles: Come with a nut-bolt or pin-cotter pin assembly, they are ideal for applications where eye-end fittings cannot be used but still require a secure, long-term connection.

How To Measure Turnbuckle Size

There are two important dimensions of a turnbuckle: thread diameter and tensioner or body length. Thread diameter is directly related to the working load limit, and the stronger the turnbuckle is required, the larger the diameter should be.

Body length is the difference between the turnbuckle “open” (end fitting fully extended) and “closed” (end fitting fully retracted). It is the amount of tension a turnbuckle can withstand and is an important measurement.

The image below shows different entry sizes. “A” indicates the thread diameter and “BB” indicates the body length. common A are 1 1/2 turnbuckle, 3/4 turnbuckle, 3/8 turnbuckle, 5/8 turnbuckle, 1/4 turnbuckle.

How Does A Turnbuckle Work

We use turnbuckle tensioner to adjust the slack or length, usually it works as below.

When the end fitting is screwed in and the body is turned in one direction, the liner is pushed out of the body and stretches to relieve tension on the portion of rope or cable it is attached to.

If the body is turned in the opposite direction, the liner is pulled toward the center and retracts to increase tension.

The amount of tension applied depends on the spacing of the two nuts when connected (called “closure”) and the material of the particular turnbuckle.

Who Supplies Top Quality Turnbuckles?

Selecting and using the right turnbuckle is critical to a safe and reliable project. Since 2009, Sail Rigging has been helping you select the right turnbuckle for every application and can even tailor it to your application.

US type drop forged turnbuckles(According to Crosby turnbuckle standard), DIN1480 turnbuckles, DIN1478 turnbuckles, Australian type turnbuckles, JIS type turnbuckles… no matter which standard turnbuckle you need, what material the turnbuckle is made of (carbon steel turnbuckles, stainless steel turnbuckles), the experts at Sail Rigging can guide you and provide quality products. Contact us now.

FAQ

- How do I choose the right size turnbuckle for my application?

The size of the turnbuckle depends on factors such as the load capacity and desired tension. Refer to manufacturer specifications and guidelines for selecting the appropriate size.

- Can turnbuckles be used in outdoor environments?

Yes, galvanized or stainless steel turnbuckles are suitable for outdoor applications as they offer corrosion resistance against environmental elements.

- What is the maximum tension capacity of a turnbuckle?

The maximum tension capacity varies depending on the type and size of the turnbuckle. Refer to manufacturer specifications for exact capacity ratings.

- Can turnbuckles be used for lifting applications?

Turnbuckles are not designed for lifting heavy loads. It’s recommended to use dedicated lifting equipment for such applications.

- How often should turnbuckles be inspected for wear and tear?

Regular visual inspections should be conducted to check for signs of wear, corrosion, or damage. Replace any worn or damaged turnbuckles immediately to prevent safety hazards.

- Can turnbuckles be used for angular adjustments?

Turnbuckles are primarily designed for linear tensioning applications. For angular adjustments, additional hardware or specialized fittings may be required.

- Are turnbuckles reusable?

Yes, turnbuckles are reusable as long as they are in good condition and properly maintained. Inspect turnbuckles before reuse to ensure they meet safety standards.

- Can turnbuckles be used in high-temperature environments?

Stainless steel turnbuckles can withstand higher temperatures compared to galvanized turnbuckles. However, it’s important to consider the specific temperature limits of the materials used.

- How do I prevent turnbuckles from seizing or getting stuck?

Apply a lubricant or anti-seize compound to the threads and moving parts of the turnbuckle to prevent seizing or corrosion.

- Which are common type of turnbuckles?

Eye and eye, hook and eye, hook and hook, jaw and eye, jaw and jaw are common turnbuckles, pls refer to the size and working load limit you need.

- Could you provide other type of turnbuckles?

Yes,In addition to the five common turnbuckles, we also offer a variety of other types of turnbuckles, including deck rigging turnbuckles, hand-crimped turnbuckles, and press-fit turnbuckles. Of course, we can also provide custom turnbuckles based on your requirements or drawings.