What Is A Chain Binder?

Chain binder, called load binder or chain tensioners, are important tools for transporting and securing heavy equipment or cargo. They tighten a tie down chain when securing loads during transport, ensuring cargos are securely fixed in place. Chain binder are used to tighten the chain firmly on the load to prevent it from shifting or falling off during transport. Chain binder usually consists of a ratchet mechanism and hooks at both ends to connect the load to the anchor point. The ends of chain binder have a tension hook at each end that can be connected to the chain and is equipped with a handle to increase the tension. The combination of chains and binders can solve the most difficult large and heavy load tying jobs of all tying methods.

Table of Contents

2 Types Of Chain Binders

According to different fastening methods, load binders could be divided into two basic types, one is ratchet chain binder, the other is lever chain binders.

Ratchet Chain binders

Ratchet binders use two simple mechanical devices, two tension hooks and handles on each end. The handles again act as levers and are threaded. Two simple mechanical devices that multiply the force manually applied to the tie-down, ratchet binders use a ratchet mechanism to gradually increase tension until the desired tightening is achieved.

With a ratchet binder, a lever and screw work together to increase the force manually applied to the tie-down, requiring much less pulling force on the handle to apply tension.

Ratchet binders also allow for slower, smoother loading and unloading, which reduces undue stress or strain on the body. Since ratchet binders consist of gears, handles, pawls, and end fittings

Another advantage of ratchet binders is that they are safer to tighten. Ratchet binders typically have a tightening distance of 8 to 10 inches, twice that of lever binders. While tightening with a ratchet binder may take a few minutes longer, it is more controllable and ultimately safer.

Lever Chain binders

Lever binders consist of a simple mechanical device – a lever and a tension hook at each end. The lever is used to increase the force applied to the tie-down. The lever is hinged and takes up the slack by pulling on one end of the tension hook, and automatically locks after the lever rotates 180 degrees around the hinge. Some of the advantages of choosing a lever tie-down include:

Easy installation

Fewer moving parts (lower maintenance costs)

Quick fastening and release.

What are chain binders used for?

Chain binders are widely used in transport application to fasten chains to cargo securely to prevent it from moving, sliding, or falling off during transportation. They play a vital role when transporting large, bulky items or materials that require a high degree of stability to prevent damage or accidents.

-

Trucking/Transport

When ship high duty equipement or load such as lumber, steel coils, machinery, and other, we need to use load binder. Load binders will help to evenly distribute the weight and firmly secure the cargo, reducing cargo movement and potential road hazards.

-

Shipping & Maritime

Chain binders are also used to secure containers on ships. They ensure containers to fasten securely to ship deck or storage area, free from falling or causing ship instabilty, even in rough seas or adverse weather conditions.

How To Use A Chain Binder?

- Inspect chain binders in good condiftion before using. Make sure all parts, including the hook, ratchet, and tensioning mechanism no cracks, bends, or corrosion.

- Choose the right type, ratcheting type or lever type as your need or the requirements of the load and application.

- Placing the chain binder along the length of the chain, making sure to leave some room.

- Open the lever and hook it onto one of the links of the chain. Insert the free end of the chain into the slot on the ratchet shaft and pull it out until sufficient tension is achieved if ratchet load binder.

- Start tensioning the chain by operating the lever or ratchet mechanism. Lever strappers use a lever to manually tighten the chain, and ratchet strappers gradually tighten the chain by turning the handle in the appropriate direction.

- Apply tension gradually, avoiding over-tightening the chain to ensure that the load remains secure.

- Securely fasten the lever or ratchet mechanism to the chain and trace point if tension is achieved.

- Check again to make sure load binder is stable before moving.

What is the working load limit for chain binders?

The working load limit (WLL) of chain binder is a key factor to secure heavy loads for transport. The WLL is the maximum weight that load binder safely carry under normal operating conditions. Load binder needs to meet the working load limit, it will keep cargo securement and prevent any risk.

The WLL of chain binder is determined by several factors, including design, manufacturing materials, and overall strength. The working load limit is usually marked on the handle of the rigging. Working load limit depends on the type and model of chain binder.

If over the WLL of load binder, will lead to serious consequences, including equipment failure, cargo slippage, and accidents. Therefore, it is critical to accurately assess the weight of the cargo and select a chain tie with a WLL that exceeds or matches the cargo weight. In addition, factors such as chain angle, environmental conditions, and dynamic forces during transportation should also be considered when determining the appropriate working life (WLL).

Regular inspection and maintenance of chain binder is also essential to ensure its continued reliability and safety. Any signs of wear, damage, or deterioration should be promptly addressed and damaged tie should be replaced to maintain its integrity and performance.

Additionally, chain binder must be used with appropriate chains and anchor points that are compatible with their working life (WLL).

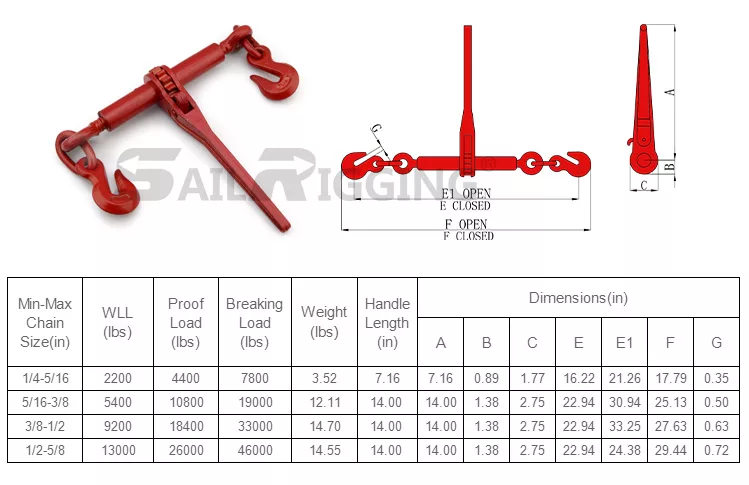

The Size and working Load limit Of US Type Ratchet Chain Binder

Conclusion

Ratcheting load binder is the most popular type in the market, 5/16-3/8 chain binder is common, there’s 4 type of working load limit, 5400lbs ratcheting load binder, 6600lbs ratcheting load binder, 7400lbs ratcheting load binder, 8800lbs ratcheting load binder. Hope this guide will be useful for you to choose chain and binder. If you have any other question about chain and binder, don’t hesitate to consult our experter. we will be glad at service.