A Complete Buying Guideline of Eye Bolts

An eye bolt, also known as a lifting eye bolt or eyelet, is a bolt with a ring on one end, commonly used to pull a load away from or towards a lifting ring in logistics handling. It is a simple design made of hardened and tempered forged steel, usually consisting of a threaded rod with a ring or eye on one end that can be screwed into a structure such as wood, steel or concrete and locked with a nut to ensure the safe working load of the lifting ring. In this artile, we will explain eye bolt application, types Of eye bolts for lifting, eye bolt load Capacity, eye bolt installation.

Table of Contents

Eye bolts, as a lifting point, are used for lifting and handling various materials. Different countries have different legislation and standards to ensure the reliability and safety of eye bolts, and they need to be checked regularly to ensure compliance with the standards.

Eye Bolt Application

Eye bolts are used as lifting or fixing points and are one of the most common rigging hardware used in places where a secure connection point is required. The shank of the eye bolt is fixed to the object, machine, vehicle or other component, and the rigging accessories are connected to the eye of the eye bolt, which is then connected to the component that needs to be moved or anchored. Eyebolts are used in a wide range of applications, including:

1. Lifting – Eyebolts are attached to the machine and then to the load so that the rigging assembly can lift it. As a safe connection point for lifting and securing the load, they are widely used in lifting machinery and fixed transportation load applications.

2. Tying and lashing – Eyebolts are fixed to structures or vehicles and used as connection points for cables, chains or wires to secure the load.

3. Suspension – Eyebolts are often used to suspend cables and other components.

4. Fencing – Eyebolts attach wires and cables to fence posts and are often used as connection points for cables to provide additional support for fences and other structures.

Types Of Eye Bolts For Lifting

There are many types of eyebolts designed for specific applications and uses. We offer eyebolts in a variety of materials, manufacturing processes, fastening types and shoulder designs so that you can find the right product for your needs. Choosing the wrong type of eyebolt can have a negative impact on your application, putting your load, equipment and personnel at risk of injury. Today we will introduce some typical types of eyebolts, shoulder eyebolts, forged eyebolts, nut eyebolts and mechanical eyebolts.

1. Ordinary eyebolt American G291 eyebolt

It is a shoulderless eyebolt with a nut, which is designed to pass through a hole and be fixed on the back with a provided nut. It can only be used for completely vertical straight pull or to support overhead loads only. If it is subjected to lateral or angular loads, it will bend and break, so it is not recommended for angular loads.

2. Shoulder eyebolt American G277 eyebolt

Shoulder eyebolts are also commonly called “shoulder-type” eyebolts. These eyebolts are designed with a shoulder at the connection between the eye and the bolt shank, which can reduce the bending stress on the bolt shank and provide more stability for the bottom of the eye. If the shoulder is properly fixed to the load, the eyebolt can be used for angle lifting. If the shoulder is not fixed correctly, it can only be used for vertical lifting, the same as ordinary eyebolts. G277 American eyebolts, shoulder with handle, partially threaded, with fixing nut, can be used for angular loads.

3. Screw Eye Bolts American G275 Eyebolts

Also known as screw eyebolts, eyebolts, tension eyes, is an eye-shaped bolt for wood, designed to be screwed into a thimble. Screw eyebolts have an eye at one end, and the threaded shank tapers gradually. They are mainly used for light applications and screwed into wood or tension anchors. They have no working load limit and are not recommended for overhead lifts or heavy loads.

4. Forged eyebolts

Forged eyebolts are made of high-strength carbon steel. After forging and annealing, they have stronger ductility and durability. After hot-dip galvanizing, electro-galvanizing and other treatments, the corrosion resistance of forged eyebolts is effectively improved. Forged eyebolts are stronger, can withstand loads up to the tensile strength of their material, and are available in larger sizes. Therefore, forged eyebolts are suitable for heavy lifting applications.

5. Mechanical Eyebolts American G279 Eyebolts

Designed for mechanical equipment, mechanical eyebolts are made of high-quality steel and have a threaded shank. The shank can be screwed directly into the threaded hole of the mechanical equipment to form a solid support that supports linear and angular loads. This type of eyebolt is most commonly used in construction and manufacturing. The shank of the mechanical eyebolt is threaded and is designed to be installed into a threaded hole specially designed as a lifting point. When equipped with a shoulder, it can withstand angular loads of up to 45°.

Eye Bolt Load Capacity

The load capacity of eyebolt depends on size and material. The larger the eyebolt, the more weight it can withstand. The material of eyebolt also affects its load capacity. For example, steel eyebolt of the same size can withstand more weight than an aluminum eyebolt.

Key factors affecting load capacity of eyebolts:

- Diameter: Different eyebolts have different thread diameters and different working load limits. The larger the diameter of the eyebolt, the higher its working load limit.

- Eyebolt design: Closed, forged or cast eyebolts are stronger and more reliable than bent eyebolts.

- Eyebolt bottom design: Shoulder eyebolts (with shoulders at the bottom of the eyebolt) are more suitable for angle lifting and have higher working load limits than ordinary eyebolts.

- Material: Different materials have different working load limits. Stainless steel eyebolts are stronger than galvanized eyebolts, but their working load limits vary depending on the grade of stainless steel.

- Lifting angle: The working load limit decreases as the lifting angle increases.

- Bolt type: Screw eyebolts, which are usually used for wood, have lower working load limits than eyebolts used for lifting.

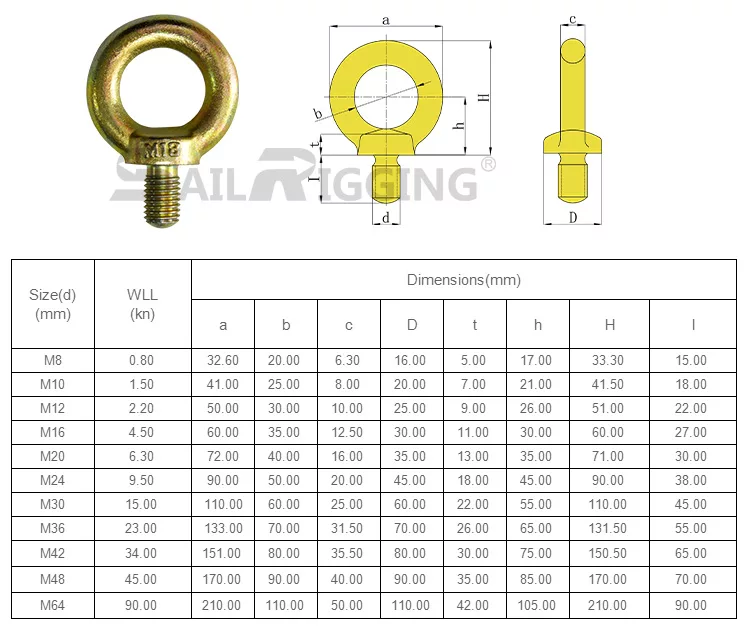

Take JIS1168 eye bolt as an example. Below is the Eye bolt capacity chart

Eye Bolt Installation

- Determine the thickness of the object you are attaching

- Before installation, always measure the thickness of the object you are attaching the eyebolt to, and make sure the eyebolt is long enough to pass through.

- Insert the eyebolt

- Identify the tapped hole of the object you need to secure the device to, and align it with the diameter of the threaded rod to ensure it is firmly fixed to the object and prevent any wobbling.

- Mechanical eyebolts require pre-drilling of the hole in the object. For drilling and tapping, the depth of the hole should be equal to the length of the device plus half the diameter of the rod.

- Tighten the eyebolt

For standard eyebolts, tighten with the provided nut to ensure a secure hold. If the unthreaded portion of the device protrudes below the anchoring object, you will need to add an additional washer to prevent the unthreaded portion from being exposed. This allows it to be securely fastened to the object without coming loose from the protruding unthreaded portion.

We hope this article helps you select and install eyebolts. If you would like to learn more about eyebolts, please contact us today.