How Many Chains and binders For A Flatbed?

Chain Binder, also known as load binder, is a device used to tighten chains when securing a load during transport. To secure cargo to a flatbed truck, strapping or chain tie-downs are required. If you need to transport heavy machinery or a large vehicle like a bobcat or heavy cargo like steel coils, then you will need chains and chain binder to secure and transport your cargo.

Table of Contents

When using transport chains to transport cargo in or on a vehicle, load binders are required to keep the load secure. Chain binders used to secure cargo cannot hold the cargo in place without chain load binder. Load binders are durable and come in a variety of styles and load ratings, and their sizes can be matched to the chain you are using.

Two Common Types of Chain Binders

There are two types of chain binders commonly used by flatbed truck drivers in the United States and Canada, lever binder and ratchet binder. The load binders commonly used by flatbed truck drivers in Australia is also a ratchet binder. Today, ratchet lashing is becoming the preferred binder because it is generally considered safer and easier to use. However, there are times when a lever load binder is the more appropriate tool. Each type of chain binders has its own pros and cons. Knowing which is better, ratchet binder vs lever binder depends on what you are transporting and how you want to secure your cargo.

What is a ratchet binder?

As the name implies, a ratchet chain tie-down uses a ratchet mechanism to tension a chain around a heavy load. This type of load binder can double up your tying method. Its screw and lever work in sync to apply force to the binder system. Not only do you not have to apply any real force to the handle, you also don’t have to struggle to tighten the chain to secure your cargo.

Ratchet type load binder are made of forged steel and are designed specifically for securing loads in chain binder applications. Ratchet load binder offer infinite adjustment for precise tying and are easier to operate than lever type load binder. Lever load binder also require manual force to tighten the load. However, the mechanical advantage provided by the ratchet makes the required loading force much lower. The ratchet lever will not “bounce” even if it is accidentally released.

What is a lever binder?

also known as lever chain or snap binders, use leverage to tighten chains and secure cargo. The tool has a tension hook on each end. The handle tightens the chain to secure the cargo, ensuring the cargo is secure.

Lever binders are generally easier to install because they are simpler in design. This type of binders stores energy in the handle, which can be more difficult to tighten because it requires more force.

Lever load binders are made of forged steel and are used to tighten chains to secure cargo. They have dual rotating levers that can apply loads faster, but the installer needs to apply relatively more manual force. If you are not careful, there is also a risk of “bounce” from the lever, which can accidentally loosen when the load is applied during installation.

How to choose the right load binder?

Chain binders are made of forged steel and come with multiple end fittings. They come in a variety of styles, sizes, and working load limits.

When choosing the right cargo tie-down, the following information is required:

Chain size

The common size is 5/16 3/8. 5/16-inch load binder can be used with 5/16-inch G70-grade transport chain or 3/8-inch G43 high-strength chain. If 5/16-3/8 load binder are used with 3/8 G70 transport chain, the strength of the load binder will be lower than the chain, and only 3/8 G43 high-strength chain or 5/16 G70 transport chain can be used.

If you use 3/8 G70-grade chain, the best choice is to use it with 3/8-1/2 load binder, so that the chain and binder are of the same strength. The size, breaking strength and working load limit are marked on the handle of the sling for better identification by the user.

Chain grade

G43 and G70 are two main grades of chain for binders.

Grade 43 high-strength chain is suitable for fixed non-transport tie-downs. Grade 70 transport chains are suitable for objects transported on flatbeds or other moving vehicles. Each chain binder can be used with any size of equipment chain to meet the corresponding application requirements. Because different grades of chain have different load limits, each chain binder is marked with chains suitable for two chain sizes to ensure proper performance.

The first measurement (smaller value) indicates the grade 70 chain size. The second measurement (larger value) indicates the required grade 43 chain size. Please choose a chain that is equal to or greater than the chain load limit to maximize your working load limit and ensure the safe transportation of goods.

WLL (strength level)

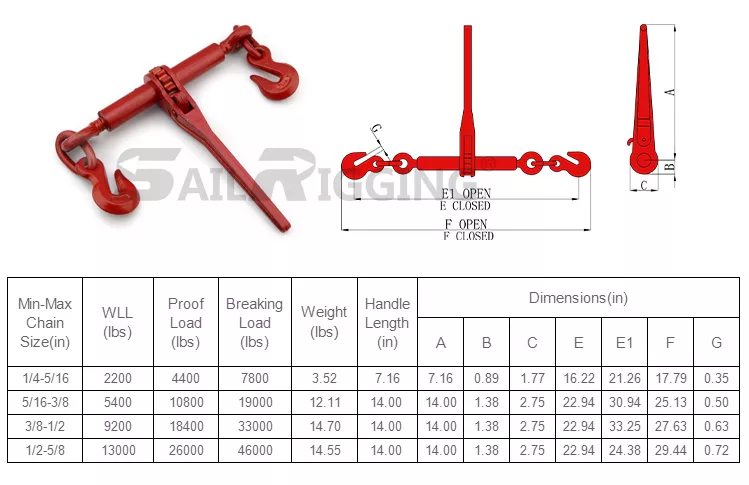

Common American forged chain binder sizes are 5/16-3/8, Sail Rigging has four working tensions, 5400lbs, 6600lbs, 7400lbs, and 8800lbs. The following are the technical parameters of US type ratchet load binder for your reference.

How Many Chains and binders For A Flatbed?

For safe cargo loading, cargo load binders are critical and must meet current performance standards set by the Federal Motor Carrier Safety Association (FMCSA). So how many chains and binders are needed for flatbed transport? The minimum number of chains required to secure the load forward by weight (pounds).

*The number of “chains required” is calculated as ((0.8 * load value) / (working load limit)) and rounded up to the nearest whole number. *

Note: The number of chains shown in the table only shows the minimum number required based on the weight of the load. They do not take into account the length, height, shape or type of load. Refer to 49CFR Parts 392 and 393 for the North American Cargo Fall Arrest and Shifting Standards to determine how many chains should be used for your application.

For example, transport tractor

Tractor > #10K, chain on all four corners

Tractor < #10K, 3 chains

Combined weight capacity of the chains must equal 50% of the weight of the tractor

Conclusion

Chain and binder are crucial in cargo control and transportation safety, so when choosing the best binder device, we need to choose the right chain binders according to our needs for the tighten device. If you need more information about transport chains and chain binders, please contact our cargo control sales experts.