What is a closed Body Turnbuckle?

A closed body turnbuckle, also known as a pipe turnbuckle, is a specially designed rigging device with a hollow tubular structure and external threads or a basket-like decoration. This metal connector with a bidirectional thread structure allows the threaded rods at both ends to be tightened or loosened simultaneously by rotating a central sleeve.

Table of Contents

Components Of A Closed Body Turnbuckle

– Hollow tube: The interior is hollow, allowing for threading or concealing other connecting components.

– External threads: The surface features standard threads, making it easy to screw into pre-drilled holes or nuts. – Joint Design: Fork-shaped, or with a fork and a rod on one end, for easy tool manipulation and aesthetics.

Differences from Open-Body Turnbuckles

| Difference | Closed Body Turnbuckles | Open Body Turnbuckles |

| Structure | Hollow Tubular | Solid |

| Application | Decoration + fastening | Pure fastening |

| Installation complexity | Requires pre-drilling or specialized tools | Direct screw-in |

Features of Closed-Body Turnbuckles

- Bidirectional Thread Design: Left-hand and right-hand threads are located on each end of the sleeve, allowing for quick adjustment with just one rotation, improving efficiency by over 50% compared to single-thread screws (refer to the 6th edition of the Mechanical Design Manual).

- High Load Capacity: Made of carbon steel or stainless steel, this compact design can withstand large lifting loads, with static loads of 5-20 tons and dynamic loads of 30%-50% of the nominal value (according to GB/T 3098.1-2010).

- Corrosion Resistance: Carbon steel turnbuckles (such as DIN 1478 and Australian Closed Body Turnbuckles) feature a galvanized surface treatment for improved rust resistance and a longer service life. The hollow tube body effectively prevents debris from entering, improving structural stability and safety, extending its service life and making it more suitable for harsh environments. Another common material is stainless steel, both 304 and 316 grades, which can pass various salt spray test requirements and are suitable for harsh environments such as marine and chemical applications.

- Easy Installation: No special tools are required; manual operation is required. Some models are equipped with a locknut for enhanced safety.

The Functions of Closed Body Turnbuckles

- Tension Adjustment: Used for tensioning and securing wire ropes and cables, such as in the installation of outdoor billboards and bridge stay cables.

- Length Fine Adjustment: Compensates for installation errors during equipment installation or pipe support, such as in the positioning of stage lighting racks and ventilation ducts.

- Safety Reinforcement: Used as temporary or permanent connectors to enhance structural stability, commonly used in construction site scaffolding and securing ship masts.

Applications of Closed Body Turnbuckles

- Construction: Used for steel structure tensioning and curtain wall support. Choose galvanized or hot-dip galvanized models to resist rain erosion.

- Power Engineering: For adjusting the tension of overhead cables, use turnbuckles with an insulating coating to prevent current interference.

- Transportation Equipment: For ship cables and truck tarpaulin fixings, 316 stainless steel is preferred.

- Agricultural Facilities: For greenhouse cable systems, ensure that the threaded rod diameter matches the wire rope (common sizes are M8-M24).

Precautions for Using Pipe Turnbuckles

- Regularly check thread wear to avoid deformation caused by overloading.

- For extended outdoor use, it is recommended to perform rust prevention treatment every two years.

- When adjusting, rotate both ends simultaneously to prevent one side from seizing.

Two Common Types of Closed Body Turnbuckles

-

DIN 1478 Closed Body Turnbuckle

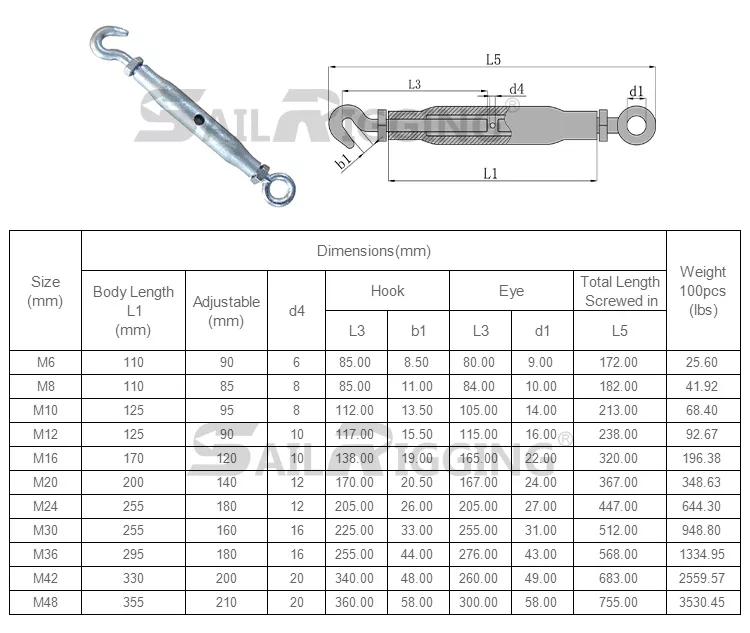

The DIN 1478 closed body turnbuckle is a common pipe turnbuckle that conforms to DIN standards and is made of 20# carbon steel and Q235 carbon steel. The tube body is a reduced-steel process, the lead screw is forged, and the surface is electroplated with a galvanized finish. Common end connectors include hooks and loops. Sizes range from M6 to M48, and the rated working loads vary depending on the size. Below is a data table for DIN 1478 loop-and-hook turnbuckles for your reference.

-

Australian Closed Body Turnbuckle

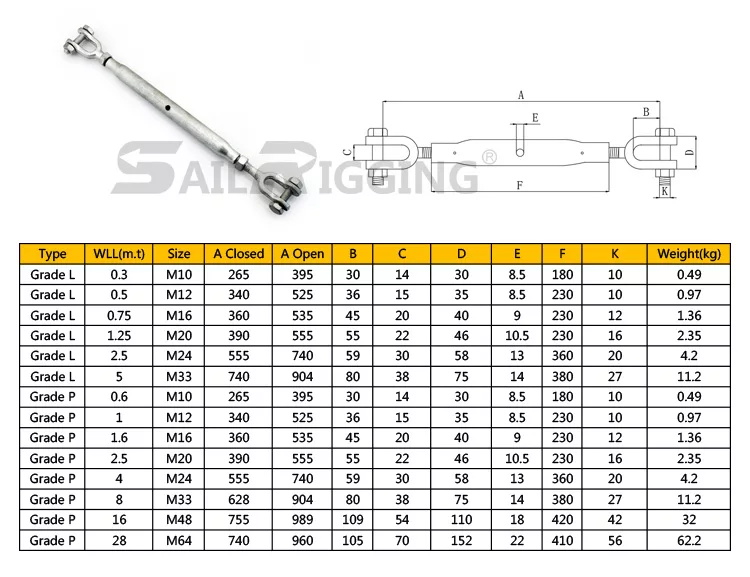

The Australian closed-body turnbuckle differs from the DIN 1478 closed-body turnbuckle in that it has a longer body and is made of a different material. The Australian closed body turnbuckle conforms to Australian standards and is made of 20# carbon steel and 45# carbon steel. The tube body is a reduced-steel process, the lead screw is forged, and the surface is electroplated with a galvanized finish. They are classified into L, P, and S grades, with sizes ranging from 10 to 45, and varying working pressures. Different sizes have different working tensions. Below is a table of Australian Closed Body Turnbuckle specifications for your reference.

Closed body turnbuckles are essential components in many industries. Choosing the right pipe turnbuckle can significantly improve project safety and efficiency. As a long-established rigging manufacturer, Sail Rigging has been deeply engaged in rigging production for 16 years, providing the highest-quality rigging hardware on the market. We understand the durability and strength requirements of your construction sites and your customers, so we will never cut corners on quality. If you would like to know more about closed body turnbuckles, please contact Sail Rigging.