Tips For Choosing Weld On D Ring

When you secure heavy equipment or oversized cargo, you must need a solid anchor point. Weld on D ring is one of important anchor point to lash, tie down.

A welded D-ring, also called a D-ring with weld-on mounting bracket, is a D-shaped anchor point consisting of a D-ring and a welded clamp. The D-ring is forged, and the welded clamp is made of bent steel. D-rings are suitable for securing and binding on truck and trailer decks, barges, and ship decks, providing rated load for slings, chains, and straps.

They’re widely used on:

- Flatbed trucks

- Trailer decks

- Barges and ships

- Industrial platforms

Whether you’re hauling machinery, construction equipment, or oversized freight, a properly installed D-ring can make the difference between a smooth transport and a costly accident.

Table of Contents

Types Of D Ring

D-rings come in two main styles: welded and bolt-on, and each has its place.

Welded D-Rings

- Permanently anchored to steel structures

- Extremely reliable under heavy loads

- Perfect for industrial equipment, trailers, and extreme cargo

- Ideal when you need a fixed, heavy-duty anchor point

Bolt-On D-Rings

- Easy to install and move around

- Great for situations where welding isn’t an option

- Can handle high loads if installed with the right bolts and torque

- Popular for flatbeds, multipurpose trucks, and removable tie-down points

How to Choose Right D Ring?

When choosing a D-ring, keep these factors in mind:

- Load Capacity – Make sure the working load limit (WLL) meets or exceeds your heaviest expected load.

- Size Matters – Check that hooks, shackles, or straps fit without binding.

- Pull Direction – The load should always pull straight; angled tension can twist or damage the ring.

- Environment – Stainless steel is best in wet or salty conditions to prevent rust.

How To Weld On D Ring

Proper installation is important for lashing and tie down. Here’s the steps to weld on D Ring.

- Prep the Surface – Remove rust, paint, grease, or any debris from the mounting area.

- Clean the D-Ring – Make sure the D-ring itself is free of dirt or oil.

- Gear Up for Safety – Wear a welding helmet, gloves, and protective clothing.

- Place and Position – Set the D-ring on the surface. Slightly grind the bracket edges to make it flush but leave a small gap for proper weld penetration.

- Tack Weld First – Temporarily secure the D-ring, then complete the weld for a strong, permanent hold.

Sizes and Load Ratings Of Weld On D Ring

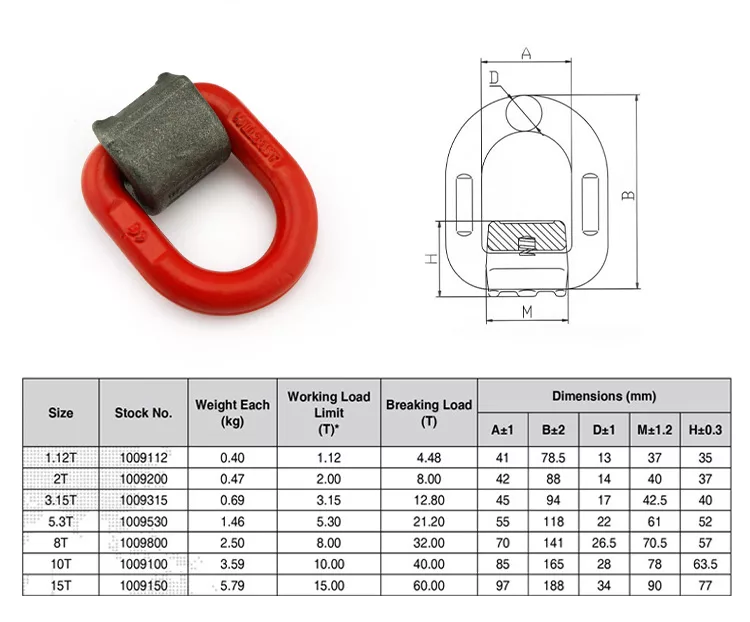

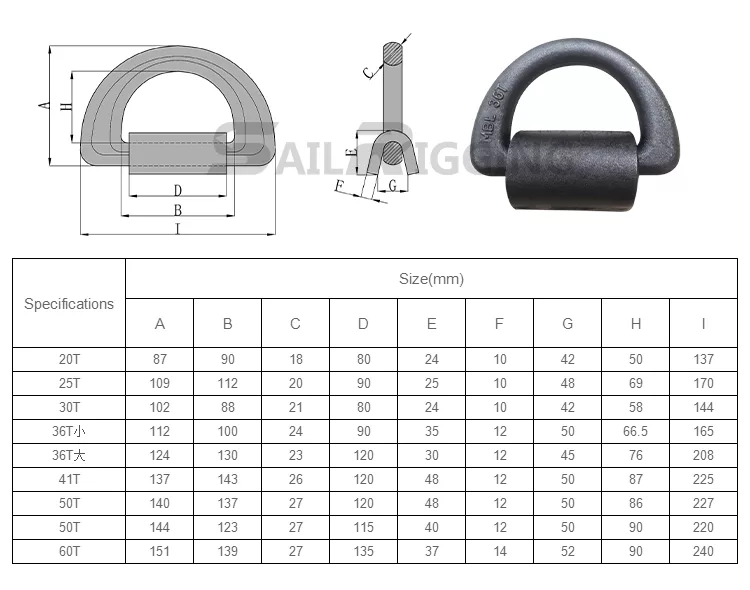

D-rings come in a variety of sizes and maximum load capacities. There’re 3 common type of weld on D Ring, The maximum load capacity (MBL) is available for D-rings of 4 tons (trailer tie donw), 20 tons, 36 tons, 50 tons and 60 tons. 4 tons is mainly for tie down on flatbed and truck. 36t, 50t, 60t is for heavy duty and deck. Here’s the size and load capacity for your reference.

The Advantage Of Weld On D Ring

- Permanent and Reliable – Won’t loosen under heavy loads

- High Load Capacity – Handles extreme weights safely

- Versatile – Works for trailers, flatbeds, and industrial decks

- Durable – Withstands harsh environments and repeated use

Tips for Safe Use Weld On D Ring

- Inspect D-rings regularly for cracks or rust

- Check bolts on bolt-on models for proper torque

- Never exceed the rated load

- Recheck tension after the first few miles

Conclusion

Welded D-rings are a simple but critical part of heavy-duty cargo securement. Choosing the right type, installing it properly, and using it safely ensures your loads stay put, protects your equipment, and keeps your operation compliant. If you want to know more about weld on D ring, please feel free to contact Sail Rigging.