Grab Hook VS Slip Hook: How To Choose Right Hook For Your Job?

Hooks are frequently used in lifting, cargo lashing, and towing. Different applications require different types of lifting hooks. There are many types of hooks, but which type is right for your job? When should you use a slip hook? When should you use a grab hook? Today, we’ll introduce slip hooks and grab hooks – their differences, types, how to choose the right hook.

Table of Contents

What Is A Grab Hook?

A grab hook is a rigging hook with a narrow throat, allowing it to securely “grab” chain links, preventing the chain from slipping. It is commonly used for securing loads, shortening chain lengths, or as an end fitting for transport chains, securely hooking the chain between links for quick and non-slip fastening.

Different Types Of Grab Hooks

Common types of grab hooks include clevis grab hooks and eye grab hooks. The main difference are the connection points. Clevis hook has a U shaped clevis and a pin for attachment, allowing for connecting to chains or rigging hardware easily and directly. This grab hook is often connected to chain, used for securing cargo, tiedown. It will make flatbed trailers safer and more efficient.

An eye hook has a solid ring at the top and is usually used with connecting links or shackles to connect chains or lifting components. The choice between an eye grab hook and a clevis grab hook depends on the existing work scenario and specific connection type preference.

Material And Grade Considerations Of Grab Hooks

Grab hooks also come in different grades, such as Grade 70 and Grade 80. Grab hooks are usually graded according to the chain they are used with. For example, a G70 grab hook is designed specifically for use with Grade 70 transport chains. We also offer G80 and G100 grab hooks. Using lower grade grab hook to match chain will effect the strength of the entire assembly. Therefore, it is important to choose same grade grab hook match same grade transport chain, ensure rigging and lashing more efficient and safer.

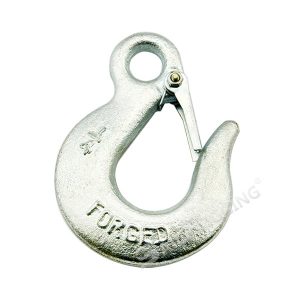

What Is a Slip Hook?

Unlike a grab hook, a slip hook has a wide, rounded hook opening. This opening is larger than the chain or sling it is used with. This allows the sling to pass smoothly through the hook opening, forming a movable loop, often called a slip knot. Additionally, slip hooks usually come with a safety latch that can be fastened to the opening of the hook.

What Are The Different Types Of Slip Hooks?

Similar to grab hooks, slip hooks mainly have two connection methods: eye-type slip hooks and clevis-type slip hooks. The main function of the hooks is the same; the difference lies in the top connection point, depending on how the hook connects to your rigging assembly. If you need a permanent connection, use an eye-type slip hook. Eye-type slip hooks have a secure closed loop that can be used with connecting links such as master links and Hammerlocks, making them ideal for dedicated slings used for repeatedly performing the same tasks. However, the disadvantage is that they are difficult to remove and not versatile.

Clevis slip hook is recommended under a temporary connection. It has a U-shape connection point with a removable pin and a cotter pin.You can remove the pin easily and connect the hook to the chain or other rigging hardware directly. It is a ideal choice for creating custom sling assemblies on site for situations where the hook needs to be changed. You could adjust different load capacity hooks without replacing entire sling assembly.

Material And Grade Considerations

Slip hooks have different grades too. Material and grade should be carefully considered before choosing a slip hook. G70 and G80 slip hook are made from alloy steel, G43 slip hooks are made from carbon steel. The grade of slip hook should be same or higher than the grade of chain. G43 chain matches G43 slip hook, G70 chain matches G70 slip hook. G43 slip hook matches G70 chain will reduce the load capacity of the entire chain assembly. This is a very dangerous mistake; always check the grade of the slip hook and chain to ensure consistency.

Grab Hook VS Slip Hook

People often confuse slip hooks and grab hooks, these hooks are different, using wrong hooks will be very dangerous. The following is detailed difference between slip hook and grab hook.

|

|

|

|

| Throat Design | wide open of throat | narrow opening of throat, could accommodate a chain link. |

| Usage | Adustability and security(with a safety latch), allowing the sling to slide for adjustment and tightening the loop | can firmly grip individual chain links, shortening the chain to a specific, non-slipping length. |

| Connection | Easily connect to most anchor points to form a sliding noose or sliding basket knot. | Quickly and securely connect to the anchor points; attach the tie-down hooks to the trailer’s anchor points for an easy and secure connection. |

| Application | Collar-style attachment method, with dynamic length adjustment

Safety tow chain and auxiliary chain provide a secure connection for towing and rescue. |

Safely shorten the chain legs to a fixed length.

Securing the chains and fastening the cargo effectively reduces the risk of the cargo slipping. |

The wide, yet narrow opening of the throat can accommodate a chain link, offering adjustability and security (with a safety lock), It provides a strong, non-slip grip on individual chain links for Connects the binding hook to the trailer’s anchor point using a collar-style attachment, providing dynamic length adjustment for a secure trailer chain and auxiliary chain, offering a strong connection for towing and rescue. Safely shortens the chain legs to a fixed length for binding chains, securing cargo and effectively reducing the risk of cargo slippage.

Conclusion

Choosing right hook is very important in rigging and lashing. No matter using chain sling, wire rope slings, safety trailer chain or binder chain, you should select right hook to reduce the risk of failure, improve load control and increase rigging efficiency.