G80 Chain Specifications & Sizes

G80 lifting chain, also called lifting chain or alloy steel chain, is high strength and toughness alloy steel chain. It is specifically designed for industrial lifting application. It is 4 time safety factor and 4 times proof load. It is made from alloy steel and subjected to be quenched and tempered, widely used in heavy lifting, rigging and towing operations. Today i will share G80 chain specification and dimensions, hope it will help you to understand G80 chains and choose the right size for your project.

Table of Contents

Chain Grade

G80 Grade 80 is a classification indicating that the chain and its testing meet specific strength standards. G80 lifting chain is high strength chain, widely used in industrial lifting application. It is conducted by international standards. High strength and safety make G80 to be better choice in construction, transportation and other heavy industries. Industries request robust, durable, reliable chains for lifting and securing heavy loads.

G80 Lifting Chains Feature

1.High Strength G80 lifting chain have a tensile strength ≥ 800 N/mm², much higher than G30 G43 G70 chains.

2. High Wear Resistance The surface of G80 lifting chains undergoes hot heat treatment, which increases its surface hardness and effectively resisting wear.

3.High Corrosion Resistance The surface of G80 lifting chains is galvanized, effectively preventing corrosion and extending its service life.

4.Safe and long lifetime G80 lifting chains undergo rigorous quality inspection and testing, ensuring their quality and safety performance.

G80 Lifting Chain Standards

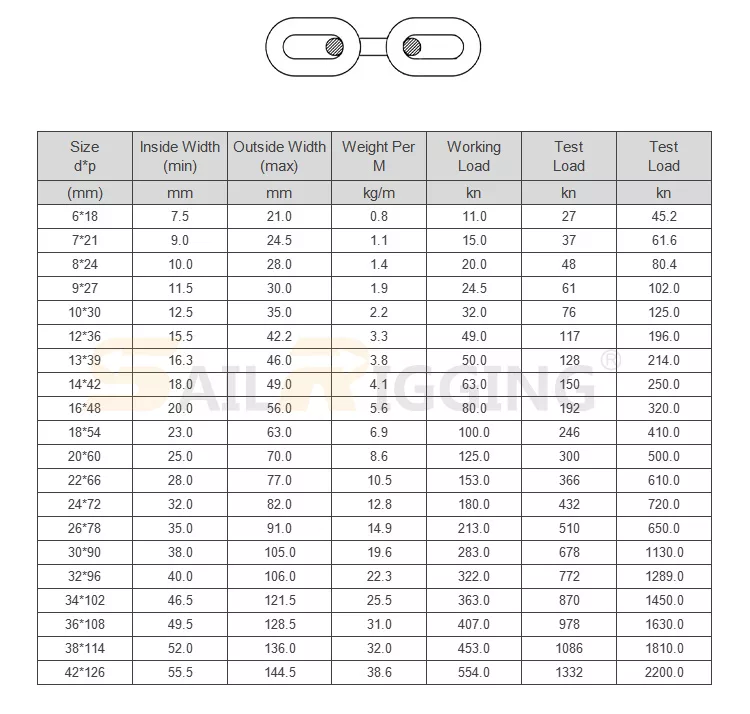

G80 lifting chain is conduct with European Standard EN818-2/ Australian AS2321/ISO9077 Lifting chains can be delivered in full rolls or in specified lengths as required. Chain diameters are from 6 mm to 42 mm.

G80 Lifting Chain Specifications

1. Common Sizes Chain size could be expressed in either millimeters or inches standard. Common millimeter sizes are 8mm, 10mm, 13mm, common inches sizes are 5/16inch, 1/2inch, 3/4inch.G80 lifting chain dimensions and working load limit can be listed following size chart.

2. Chain Material G80 lifting chains are made of high-quality alloy steel such as 20Mn2.20Mn2 G80 Chains have following advantage.

- More stable composition and higher purity, reducing internal defects and improving overall reliability;

- Manganese as the main alloying element significantly improves the strength and hardness of the chain, making G80 chain less prone to deformation or fracture when subjected to tensile or impact loads.

- Good heat treatment adaptability ensures uniform structure and stable performance after annealing or quenching, avoiding cracking or soft spots during processing.

- High yield strength ≥590MPa, tensile strength ≥785MPa, good toughness elongation ≥10%, allowing to withstand dynamic loads and accidental impacts, perfect for lifting and mining.

3. Lifting Chain Surface Treatment Lifting chain surface treatments include polishing, blackening, dipping, plastic coating, and electroplating, including black paint, electro-galvanizing, hot-dip galvanizing, and blackening, to meet the anti-corrosion needs in different environments.

G80 Lifting Chain Application

1. Lifting and Rigging

G80 chains are commonly used in cranes and hoists for lifting heavy objects in construction sites, shipyards, and other industrial settings.

G80 chains are typically used in conjunction with hooks and other components to form chain slings for safely lifting heavy loads. G80 chains are also used to secure cargo during transportation to ensure stability, especially in trucking and shipping industries.

2. Mining and Quarrying

G80 chains are commonly used in the mining industry for lifting and moving heavy mining equipment, and for transporting and securing materials in rugged environments.

3. Construction

In construction, G80 chains are used for lifting and transporting building materials such as steel beams, concrete slabs, and other heavy materials. They are also used to lift heavy machinery and stabilize equipment during installation or transportation.

4. Marine and Offshore Operations

G80 chains are well-suited for marine environments and are used in anchoring, mooring, and towing operations. Their excellent corrosion resistance makes them suitable for offshore oil rigs and vessels.

5. Logging and Forestry

G80 chains are used in the forestry industry for pulling and transporting logs, and for securing heavy machinery in rugged terrain.

6. Manufacturing and Warehousing

In manufacturing plants, G80 chains are used for handling heavy machinery, equipment, and raw materials. They are also used in overhead cranes and conveyor systems in warehouses for moving heavy loads.

7. Vehicle Recovery

G80 chains are also used in vehicle recovery in off-road, such as pulling vehicle out of mud, snow or sand. These G80 chain are suitable for reliability and paramount strength, such as construction, mining or transportation.

Conclusion

Are you looking for high strength and safe G80 lifting chain? Worried about how to choose G80 chain. Sail Rigging provide full size and types of G80 chain with various anti-corrosion treatment. Black oxide treatment, black paint, hop dip galvanization, electro galvanization ect are available. If you have any question about G80 lifting chains, please feel free to contact us.