Comparsion US Type Load Binders And EU Type Load Binders

Load binders, also known as chain tensioners, are essential tools in cargo transportation and lifting operations. These tension systems are typically used with chains. By tightening the chains and stabilizing the load, they ensure cargo is securely tied during transport, preventing it from shifting or loosening due to vibration, jolts, or external forces.

Table of Contents

Load binders are ideal load control devices for trucks, trailers, campers, and cargo ships. Heavy-duty load binders are used to secure heavy equipment and other specialized heavy cargo that requires secure lashing. There are many different types of load binders. Load binders are widely used in the United States, Canada, and Australia, common rigging styles include American, European, and Australian styles. In this article, we will analyze the similarities and differences between American and European rigging.

Similarities Of US Type Load Binders And EU Type Load Binders

1. Process: Both US Type load binders and EU Type load binders are drop forged.

2. Surface: Typically painted red, but can be customized with a custom color palette or galvanized.

3. Material: Different components vary in material, primarily made of high-carbon steel and aluminum alloy.

Differences Of US Type Load Binders And EU Type Load Binders

1. Grade

US Type load binder is graded G70, while European type load binder is graded G80.

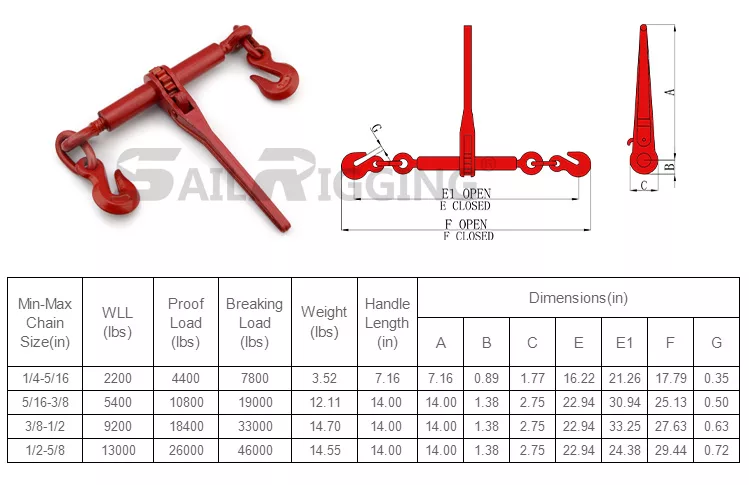

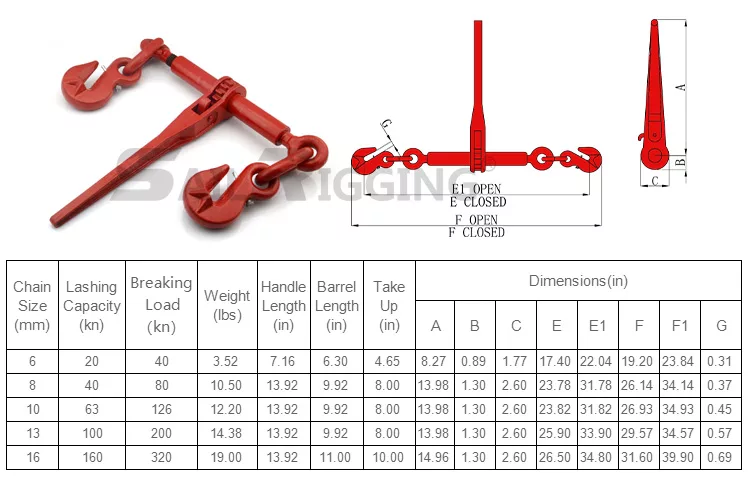

2. Specification: US type load binders use metric wire, with common sizes being 1/4-5/16, 5/16-3/8, 3/8-1/2, and 1/2-5/8. European type load binder uses imperial wire, with common sizes being M6, M8, M10, M13, and M16.

3. Hook: Taking ratchet load binders as an example, US type rathet load binders hooks lack spring pins and are conventional grab hooks. European type load binder uses winged grab hooks with spring pins.

4. Cross Pin: European type load binder has a cross pin inside the tube, and the screw rod cannot be removed. US Type load binder can include one or not (depending on customer requirements).

5. Standard: European type load binder complies with EN12195-3, while US Type load binder complies with ASTM standards.

6. Specifications: Taking ratchet rigging as an example, the specifications of American and European load binders are different.

Questions About Load Binder

1. What are the two types of load binders?

Common types include ratchet, lever, and spring load binders. Ratchet load binders use a ratchet mechanism to easily tighten the chain. They come in a variety of sizes and are suitable for chain tighteners. Chain tighteners: This is the most common type of chain tightener. They use a ratchet mechanism to easily tighten the chain. They are available in a variety of sizes to accommodate different chain sizes. Lever load binders: Use a lever to tighten the chain. They are easy to use and can be tightened quickly. They are ideal for short chains and light loads. Spring load binders: The most convenient to use, require no tools, and use a spring mechanism to snap the chain into place. They are ideal for light loads and short chains.

2. Are ratchet binders better than lever chain binders?

Whether ratchet or lever-type tie-downs are better depends largely on the specific application, load requirements, and user preference. Both types of tie-downs serve the same basic purpose—securing a load during transport—but they differ in their mechanism, ease of use, and safety features.

3. What are the mechanical advantages of lever type load binders?

Lever type load binder utilize mechanical advantage to reduce the manpower required to secure a load. When using lever-type tie-downs, tension can be applied and released quickly. Operators should exercise caution, as the handles can jerk suddenly.

4. What is the safest way to manually release a load binder?

To release a load strap, use an open hand (do not grip the strap handle). Keep your body away from the strap and push the lever. Exercise extreme caution when releasing tension, as the handles can snap back quickly.

The decision between American and European standard tie-downs should be based on your specific needs, transport environment, and market standards. Regardless of which standard you choose, ensure load binders meet relevant safety and load requirements to ensure a safe and efficient transport. If you are still hesitating about what kind of load binders to choose, Sail Rigging will provide you with a flatbed truck chain rigging method, which is your best choice.