A Comprehensive Guide to DIN741 Wire Rope Grips

Wire rope grips are essential components across various industries, providing a secure connection for wire ropes in lifting, rigging, and securing applications. Among the many standards and types available, DIN 741 wire rope grips stand out for their durability, sophisticated design, and versatility. This article will delve into the features, advantages, applications, and considerations of custom DIN 741 wire rope grips.

Table of Contents

Wire rope grips, also known as “U-bolts,” “bulldog grips,” or “wire rope clamps,” are essential components in lifting, rigging, and securing applications. They are primarily used to clamp a looped wire rope, forming an eye. They consist of a U-bolt and a saddle secured by two nuts. The DIN741 wire rope grips are relatively common cable clips. Today, we will delve into the components, features, applications, customization, and considerations of DIN741 wire rope grips.

DIN Standards

DIN, the abbreviation for the German Institute for Standardization (Deutsches Institut für Normung), is a recognized organization that develops and maintains standards for various products and services. DIN standards ensure that products meet specific safety and performance criteria, making them trustworthy in industrial applications. DIN 741 wire rope grips must adhere to this DIN standard, ensuring quality and reliability in critical applications.

The DIN 741 wire rope clamp consists of a U-bolt and a saddle secured by two nuts. Its design and production standards conform to BS EN 13411-5.

The Parts Of DIN 741 Wire Rope Grips

- U-bolt – This is the U-bolt that passes through the two halves of the wire rope.

- Saddle – This is the metal base at the “live” end of the wire rope, secured by the U-bolt.

- Nuts – Two nuts are used to tighten the U-bolt, clamping the wire rope between the saddle and the U-bolt.

DIN741 Feature

- Material: Saddle is malleable cast iron, U-bolt is Q235 carbon steel.

- Surface: Commonly electroplated galvanized.

- Process: Casting.

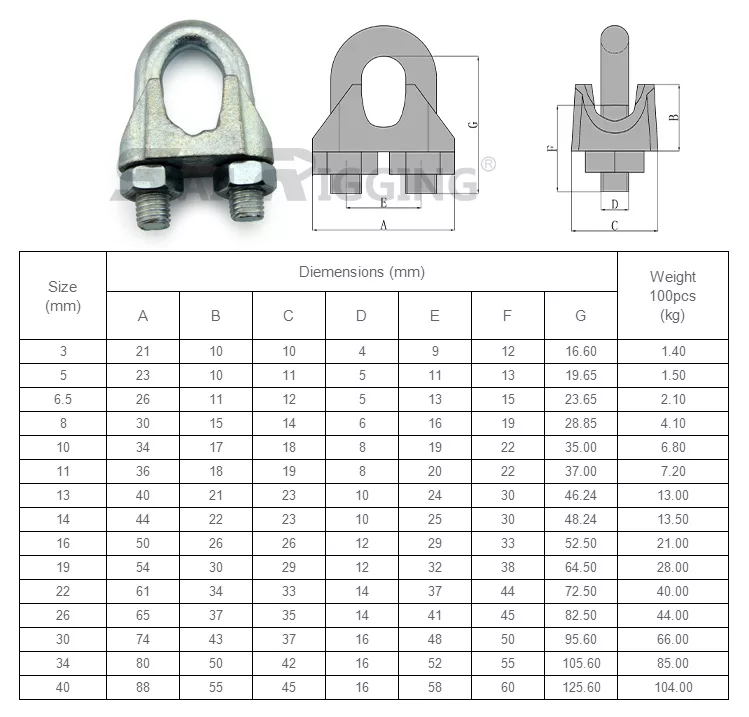

- Size: 3mm-40mm, the following is the size chart of DIN741.

- Standard: DIN741 German Standard.

How To Use Wire Rope Grips Correctly: Avoiding Common Mistakes

- The size of the wire rope clamp should match the wire rope diameter; selecting an inappropriate wire rope clamp size can result in wire rope damage or insufficient clamping force.

- Improper installation of a wire rope clamp can reduce operating efficiency by 40%.

- Larger wire rope diameters require more wire rope clamps with the appropriate tail length to ensure consistent working load limits. For example, when the proper torque is applied to the nut, the terminal efficiency for 3mm to 22mm wire ropes is 80%, and for 25mm to 89mm wire ropes, it is 90%.

- DIN 741 clips are not suitable for critical or lifting applications and are typically suitable for static, tensioning, or general use.

- Regular inspections are crucial to ensure the nut remains tight and the clip is in good condition. Wear, misuse, or overloading of wire rope clips can cause material deformation.

How Can You Visually Identify The Quality Of DIN 741 Wire Rope Grips?

- Galvanized: Surface treatment is zinc-plated for rust and corrosion resistance, ensuring durability.

- Clamp: Made of carbon steel for durability.

- Thread: Fine, burr-free, and well-made.

Of course, beyond appearance, it’s even more important to check whether the dimensions meet standards, are within tolerance, and whether they can pass tensile tests. If corrosion protection is a concern, the thickness of the zinc coating is a key consideration. These factors require specialized testing equipment. If you’d like to learn more about wire rope clip testing, contact Sail Rigging. We have over ten pieces of testing equipment and are equipped for in-house testing. More information you want to know about wire rope grips, just feel free to contact Sail Rigging.

FAQ

-

What size terminal should I use for a jacketed wire rope (e.g., 10mm)?

The size of the clamp must match the thickness of the wire rope. For a 10mm wire rope, a 10mm clamp must be selected.

-

If I have a 5mm wire rope, which type of wire rope do I need? When I coil it and want to secure it, do I need a 10mm or 5mm thick wire rope?

The nominal strength of a wire rope always refers to the actual thickness of the wire rope. So if you need to use a cable clamp with a 5mm thick wire rope, you will need a 5mm thick clamp. The wire rope design allows for 2x the wire rope to pass through the bracket.