A Comprehensive Guide to DIN1142 Wire Rope Grips

Wire rope clamps, also known as wire rope clips or bulldog clips, are a quick wire rope fastening device. Wire rope clamps can be used to form load-bearing loops at the end of steel cables or wire ropes, or to connect two steel cables with a lap joint. Wire rope clips are easy to install and do not require specialized crimping tools; only a wrench is needed for installation.

Wire rope clips are not used for slings, but are mainly used for securing the ends of wire ropes on crane cables or winches, passing a section of wire rope through an eye bolt or shackle, or for perimeter cables in places such as docks and parking lots. Wire rope clamps come in two types: U-bolt clamps and double saddle clamps. Sail Rigging sells various models that comply with different global standards, such as the US Federal Specification FF-C-450, German standards DIN 741 and DIN 1142, etc. Today we will introduce a common DIN1142 U-bolt clamp.

Table of Contents

What is a DIN1142 clamp?

DIN 1142 is a German industrial standard published by the German Institute for Standardization (DIN). This standard specifies the dimensional tolerances, material requirements, mechanical properties, and assembly structure of wire rope clamps. Compared with other wire rope clamps, DIN1142 clamps are more robust and highly consistent with the requirements of EN13411-5, providing higher clamping efficiency and greater reliability.

DIN 1142 Wire Rope Grip Parts

The DIN1142 wire rope grip have three parts: a U-bolt, a saddle and two nuts.

U-bolt

Made of carbon steel, the U-bolt applies clamping force to the dead end of the wire rope.

Saddle

The saddle supports the live end of the wire rope and helps prevent the wire rope from being flattened or deformed during tightening.

Nuts

Usually flanged nuts, unlike the ordinary hexagonal nuts of DIN1147, used to evenly tighten the U-bolt and secure the assembly.

DIN 1142 Wire Rope Clamp Material

Usually made of carbon steel and malleable iron, with a malleable iron body and Q235 carbon steel U-bolt for higher strength. Of course, we also accept customization services for other materials. If you have special requirement of material, please feel free to contact Sail Rigging.

DIN1142 Surface Treatment

The common surface treatment for DIN1142 is electroplated zinc plating, which is more economical, practical, and widely used.

DIN 1142 Wire Rope Clamp Application

- Lifting and hoisting components

- Marine and offshore drilling rigging

- Construction and infrastructure projects

- Industrial tensioning systems

- Heavy machinery equipment installation

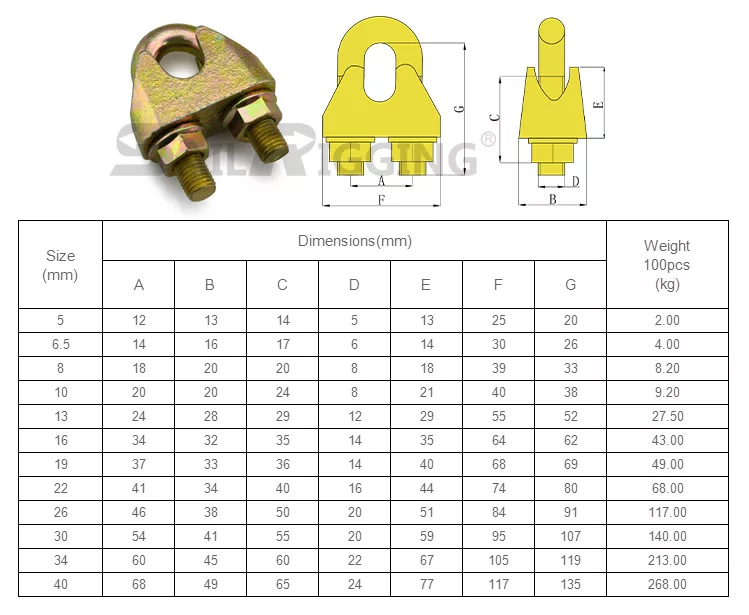

DIN1142 Wire Rope Clip Size Chart

The following is DIN1142 wire rope clip size chart for reference, when choose wire rope clip, pls make sure if dimensions meet your demands. Special demension is available, you need to contact Sail Rigging for customized wire rope clip service.

Installation and Safety Precautions

Install wire rope clip correctly is important for securing the wire rope. Below are the precautions for installing wire ropes.

1. The size of the wire rope clamp matches the wire rope diameter. If the clamp is too small or too large, it may be not safe to fasten the wire rope.

2. Use the recommended number of wire rope clamps at each connection end. A minimum number of wire rope clamps is required depending on the wire rope diameter. Using fewer wire rope clamps than specified may lead to reduced efficiency or even failure.

3. Tighten the nuts to the specified torque. If a nut isn’t tightened to the specified torque, it can lead to dangerous failures.

4. Regularly check for corrosion, wear, or deformation. If any of these conditions are present, replace the clamp immediately.

DIN1142 VS DIN741 Wire Rope Clip

We have shared another type DIN wire rope clip before, today i will show you the difference between DIN1142 and DIN741 as below.

| Feature | DIN 1142 Wire Rope Clip | DIN 741 Wire Rope Clip |

| Standard | DIN 1142 (German Standard) | DIN 741 (German Standard) |

| Duty Level | Heavy-duty | Light-duty |

| Typical Applications | Lifting, hoisting, marine, industrial rigging | Static fastening, fencing, general-purpose use |

| Load Capacity | Higher holding efficiency | Lower holding efficiency |

| Suitable for Lifting | Yes (when correctly installed and specified) | No |

| Wire Rope Diameter Range | Approx. 6 mm – 60 mm | Approx. 3 mm – 40 mm |

| Saddle Type | Forged or pressed steel saddle | Malleable cast iron saddle |

| U-Bolt Material | Carbon steel or alloy steel | Q235 carbon steel |

| Manufacturing Process | Forged / pressed | Casting |

| Surface Finish | Hot-dip galvanized, electro-galvanized | Mainly electro-galvanized |

| Corrosion Resistance | Higher (especially HDG version) | Moderate |

| Holding Efficiency | Higher (typically 80–90% with correct installation) | Lower (not recommended for load-bearing) |

| Safety Level | Suitable for demanding and safety-critical applications | For non-critical applications only |

| Price Level | Higher | Lower |

| Recommended Usage | Professional rigging and industrial systems | Temporary or non-load-bearing assemblies |

Conclusion

Wire rope clips may seem simple, but they are crucial. No matter which size DIN1142 wire rope clip you choose, it should meet the requirements of the task and environment. If you have any question about wire rope clips, please feel free to contact Sail Rigging.

FAQ

1.What size wire rope clip should I use for a 10 mm wire rope?

Use a 10 mm DIN 741 wire rope clip. The clip size must always match the rope diameter.

2. If I have a 5 mm wire rope, do I need a 10 mm clip when looping it?

No. The nominal wire rope diameter remains 5 mm, even when doubled. You should still use a 5 mm clip.