Turnbuckle Size, Load Rating: How To Choose Right Turnbuckles?

Turnbuckles, also known as tensions, are widely used in most tension related construction and rigging to tighten and adjust cables, ropes and wires.Like other rigging hardware, right use is essential for safety and effectiveness. Improper use will cause accidents, injury, even property damage. Today, we will introduce the parts, dimensions, working load, how to select right turnbuckles.

Table of Contents

What is a Turnbuckle? & Components of a Turnbuckle

A turnbuckle is an adjustable device consisting of three main parts: a body, a right-hand threaded end fitting, and a left-hand threaded end fitting. Turnbuckles come with various types of end fittings (hook, eye or U-shaped, rod type), and the two ends of the same piece of hardware can have different fitting combinations. By adjusting the length of the fitting, the tension of the connected rope or cable is changed. Furthermore, depending on the safety requirements, turnbuckles can have an open structure or a tubular structure.

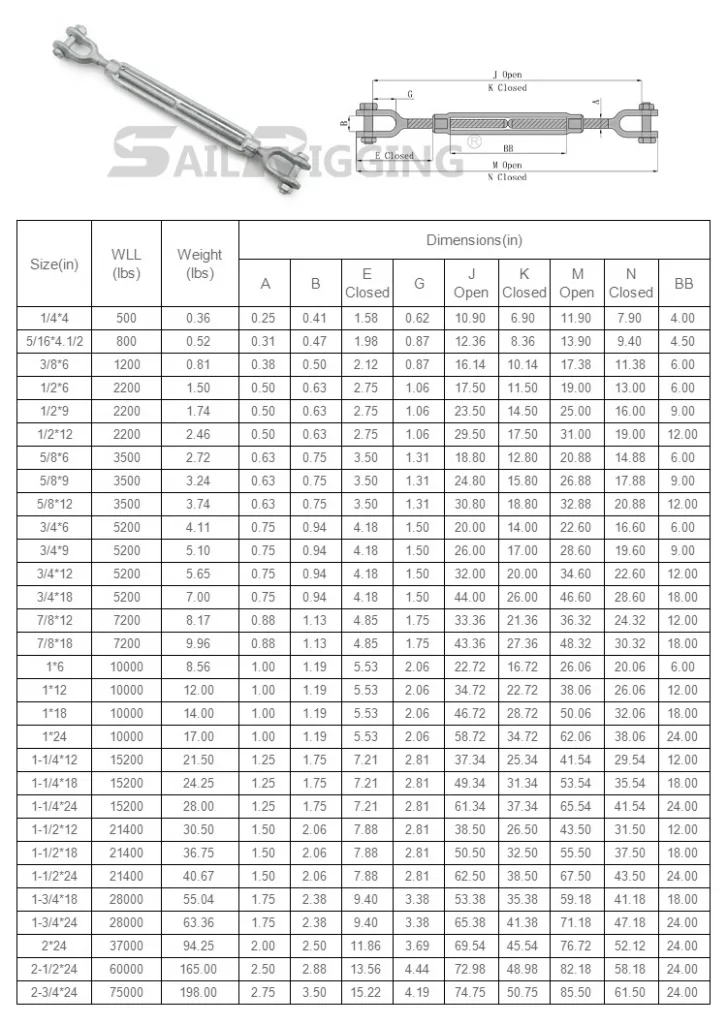

Turnbuckle Dimensions

When select turnbuckles, we need to consider its dimensions. This dimension is the size of thread, means the load capacity. It means the strength meets or exceeds the strength requirements of the components, and then selecting the appropriate adjustment length. Thread diameter and adjustment length are two key dimensions of a turnbuckle. The thread diameter determines the strength and load capacity of the turnbuckle, and the internal length of the body determines the adjustment range of the turnbuckle, which is the difference in internal length between the fully open and fully closed positions of the bolt body. Taking US drop forged turnbuckles as an example, common thread diameters include 1/4 inch, 5/16 inch, 3/8 inch, 1/2 inch, 5/8 inch, 3/4 inch, 7/8 inch, 1 inch, 1-1/4 inch, and 1-1/2 inches. Common adjustment lengths include 4 inches, 6 inches, 9 inches, 12 inches, 18 inches, and 24 inches.

Turnbuckle Rated Load

The rated load of turnbuckles, refers to the maximum allowable working load of the turnbuckle. Turnbuckles with different thread diameters have different rated loads. Taking US drop forged turnbuckles as an example, 1/4-inch turnbuckle has a load capacity of 500 lbs. 5/16-inch turnbuckle has a load capacity of 800 lbs. 3/8-inch turnbuckle has a load capacity of 1200 lbs. 1/2-inch turnbuckle has a load capacity of 2200 lbs. 1-inch turnbuckle has a load capacity of 10000 lbs. For overhead lifting, ensure that it conforms to ASTM F-1145 or similar standards and has a safety factor of 5:1.

Turnbuckle End Fittings

Turnbuckles come with various types of end fittings (hook, eye or jaw , stub), and the two ends of the same piece of hardware can have different combinations of fittings. The combination of end fittings depends on what the turnbuckle needs to connect to and whether the solution is permanent or temporary. Hooks are used for temporary connection points that may need frequent connection and disconnection. Jaws are used for connecting to non-opening connection points, such as eyebolts or connecting rings. Eyes are used for connecting to opening connection points, such as shackles or quick-release rings. Common turnbuckle end fitting combinations include hook-eye, hook-hook, eye-eye, eye-jaw, jaw-jaw, and stub and stub.

Conclusion

Turnbuckles size,turnbuckle rated load are vital for safe tensioning. Understanding size, rated load, type, end fitting will ensures your project safer and more effcient. If you have any question about turnbuckle size, turnbuckle rated load, feel free to contact Sail Rigging.