A Guideline To Hammerlock: The Types And How To Assemble Hammerlock

What is a Hammerlock?

A hammerlock, also known as a chain connector, connect link, butterfly buckle, double ring buckle and couples chain links. It consists of a recessed pin extending through each end of a sleeve. Made of alloy steel, quenched and tempered, and tensile-tested, hammerlocks are suitable for Grade 80 and 100 applications. They connect chains to the legs of chain slings or master links to chain slings when internal chain space is limited. They are also used to connect winch hooks to steel or synthetic winch ropes. Hammerlocks can be used as towing chain extenders, particularly when the safety chain on RVs, campers, or trailers is too short. Today, we will focus on how to use a hammerlock as a towing chain extender.

Table of Contents

Common Hammerlocks

-

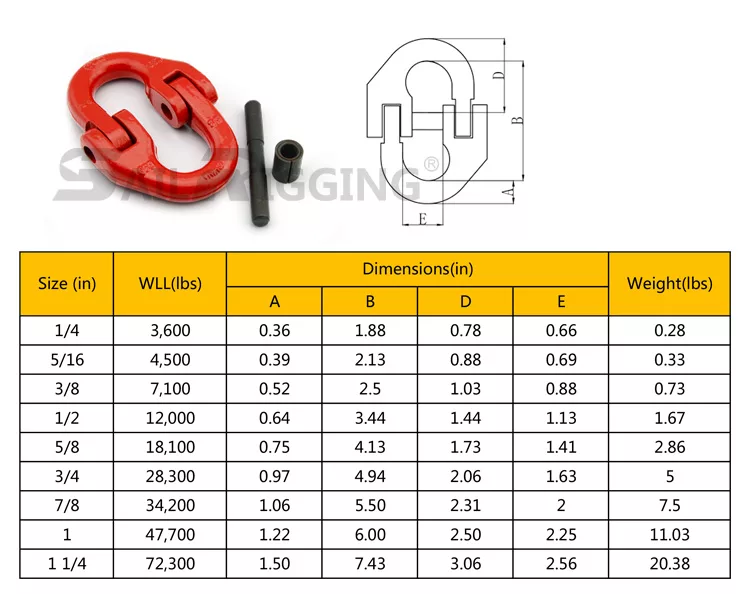

US Type Hammerlock A337

US type tandard hammerlock is made of 35CrMo alloy steel and comes in sizes from 1/4 to 1 1/4. Its maximum working load is 72,300 lbs. It is commonly finished in red plastic spray.

-

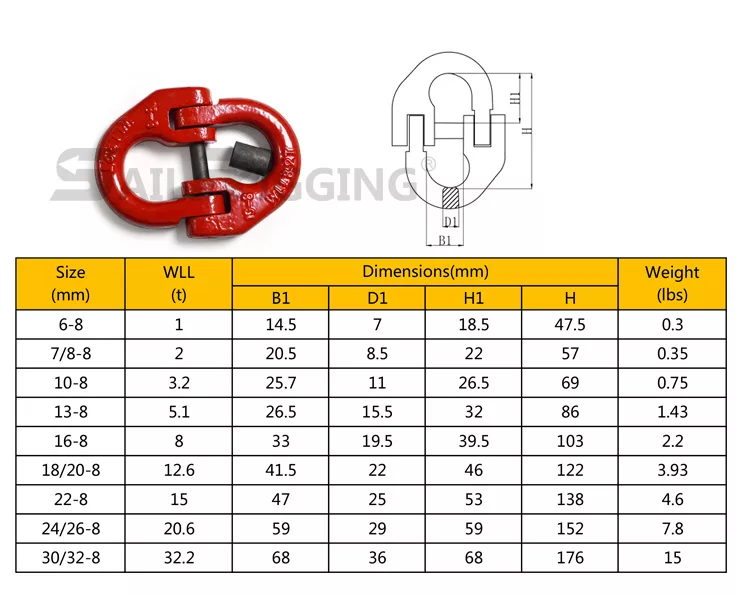

European Type Hammerlock

Conforming to European standards, it’s made of 35CrMo alloy steel and available in sizes from 6mm to 32mm. Its maximum working load reaches 32.2 tons. Common finishes include yellow and red spray-coated finishes.

Advantages of the Hammerlock

1. More Space. The Hammerlock acts as a trailer chain extender. When lowered, it provides more space between the ends than the vehicle’s original drawbar. This makes connecting a shackle or hook easier and more comfortable.

2.Easy Assembly and Disassembly: The pin and snap-lock system allows for quick and easy installation and removal, without tools. Simply hammer the pin into the center of the chain link to secure it, and easily release it by driving it out.

3.More Secure and Reliable Connection. Once assembled, the Hammerlock provides a very secure connection that is difficult to accidentally remove.

4. Wider Applicability. The Hammerlock’s open design makes it easier to connect various types of components, such as shackles, hooks, and different end fittings, especially when the links in the chain are too small. Hammerlocks are particularly effective for modern truck hitches with unusually shaped safety chain brackets.

5.More durable. Hammerlocks are made from high-strength, heavy-duty materials like G80 and G100 grades, and undergo a die-forging process to withstand high loads and harsh conditions.

6.Easier to connect with difficult-to-connect hitches: They are particularly useful for modern truck hitches with unusually shaped safety chain brackets, making connecting safety chains easier than with traditional hitches.

7.Heavy and durable: Hammerlocks are made from high-strength, heavy-duty materials like G80 alloy steel to withstand high loads and harsh conditions.

How to install a hammerlock?

1.Join the two coupling link halves together and place the tube in the center of the hammerlock.

2.Insert the load pin through the hammerlock. The load pin should fit snugly into the hammerlock, leaving no gaps or play.

3.Use a punch to press the load pin in until the end of the pin protrudes through the forging surface. Use a hammer or mallet to press the punch into the load pin and push it completely into the coupling link. The end of the load pin should be flush with the forging surface, indicating it is fully seated.

After the load pin is fully seated, inspect the hammer lock for any signs of damage or defects. Check that all components are properly aligned and seated, and that there are no gaps or voids between them.

Notes:

1.Add oil regularly. If you experience difficulty hammering in the hammer during installation, add some oil to the intermediate bushing. Also, add oil regularly every three months or so to keep it moist and prevent rust, thus extending the life of the hammer lock.

2.During assembly, do not reverse the two coupling links.

3.Most importantly, always follow proper lifting and rigging procedures and never exceed the rated load capacity of any component or system.

For more information about hammerlocks, please feel free to contact Sail Rigging. We have been dedicated to rigging production and processing for many years and will provide you with one-stop rigging solutions.