One Technology for Customized Load Binder: Coated Sand Casting

Load binders are common tools used in logistics and transportation lashing. Common ratchet load binder, lever load binder, and recoilless chain load binder utilize forging processes. Today, we will discuss a different technology process- coated sand, a process for customized load binders.

Table of Contents

What is coated sand casting?

Coated sand casting is an advanced sand casting technique that coats the sand grains with a resin film to enhance their strength and precision. Coated sand consists of quartz sand, resin, and a curing agent. Heating melts the resin and encapsulates the sand grains, forming a strong sand mold. The heating temperature is typically controlled between 150-250°C, and the curing time varies depending on the size and thickness of the sand mold, typically 1-3 minutes.

The Feature of Coated Sand Casting

Coated sand offers suitable strength and fluidity, resulting in clear, dense sand molds and cores, allowing for the production of complex core shapes. The surface quality of the molds and cores is excellent, with surface roughness reaching Ra = 6.3-12.5μm and dimensional accuracy reaching CT7-CT9. High production efficiency, excellent collapsibility, and easy cleaning of castings make this process widely used in the production of complex castings.

The Function Of Coated Sand Casting

Coated sand can be used to make molds and cores. Coated sand molds and cores can be used in conjunction with each other or with other sand molds and cores. Coated sand can be used not only in metal gravity casting and low-pressure casting, but also in iron sand coated casting and hot centrifugal casting. It can be used not only in the production of cast iron and non-ferrous alloy castings, but also in the production of steel castings.

Applications of Coated Sand Casting

Coated sand is particularly effective for sand cores with complex shapes and high requirements for mold cavity surface quality, high dimensional accuracy, and complex shapes. The coated sand casting process is not only suitable for the production of high-precision castings such as automotive parts, pumps and valves, and engineering machinery, but also suitable for the customized processing of tight rigging, especially for small and medium-sized batches and high-demand customized processing of tight rigging. If you have customized tight rigging needs and have high requirements for surface dimensions, you can consider the coated sand process.

Process of coated sand casting process

1. Model preparation

2. Coating: Heat to 180-220℃ to melt the resin and evenly wrap the sand particles.

3. Coated sand shell production

(1) Fill the mold with coated sand and shoot it into the heated mold cavity (temperature 180~250℃) through a core shooting machine.

(2) The resin is quickly cured by heat (20~60 seconds) for 1-3 minutes to completely cure the resin and form a high-strength sand mold.

4. Demolding and shell removal: Open the mold and remove the cured sand shell.

5. Mold shell finishing: Clean burrs and repair defects (such as filling sand with coated sand and then locally heating and curing). 3. Mold Shell Assembly

6. Pouring and Cooling: Molten metal is poured into the sand mold. The pouring temperature is adjusted according to the metal type, such as 1300-1400°C for cast iron.

7. Shelling and Cleaning

Precautions for Coated Sand Casting

Control the amount of resin and curing agent added. Excessive amounts will increase the brittleness of the sand mold.

Heating temperature and time must be precisely controlled to avoid over-curing or under-curing the resin.

Sand molds should not be stored for extended periods; it is recommended to be used within 24 hours to prevent moisture absorption and loss of strength. These products are now available in our store. Our castings utilize advanced technology, resulting in stable structures, fine surface treatments, short proofing cycles, and flexible production cycles.

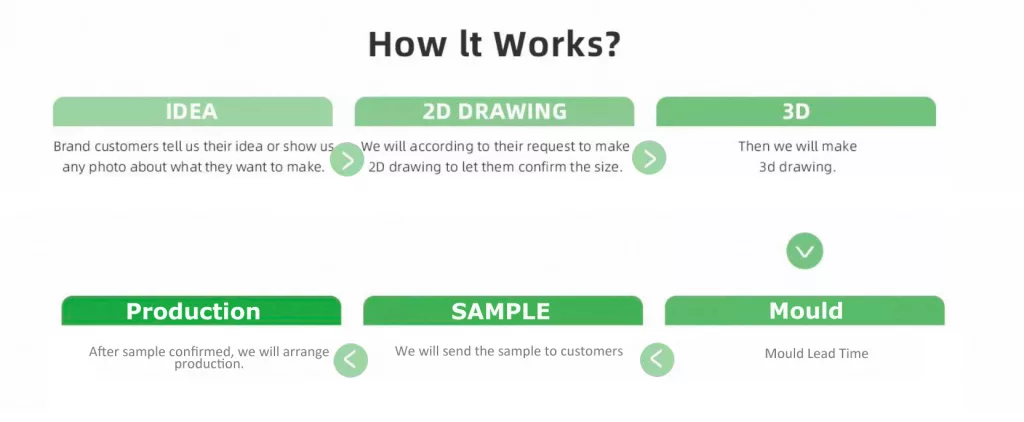

How To Customize Load Binder?

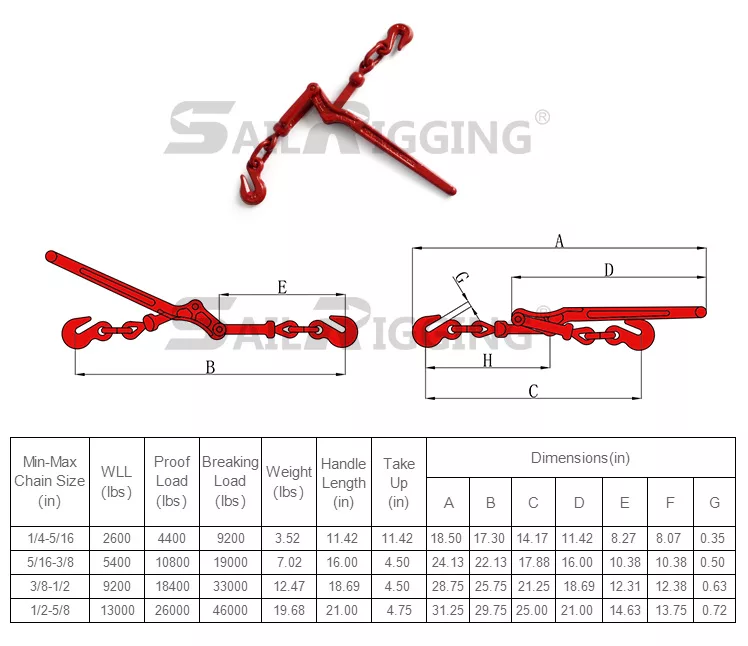

Discover a diverse range of load binders to your binder requirements at Sail Rigging, you will find standard US type ratchet load binder, US type lever load binder, Australian ratchet type load binder, European ratchet type load binder, etc. The following is the size chart of US type lever load binder.

If these don’t meet your requirements, you could contact us about customized load binder. The following is the process of customized load binders. Sail Rigging is not only focusing on standard rigging hardware for 16+ years, but also could help you to provide customization solution. Contact Sail Rigging right now if you need customized load chain binders.