A Guideline for Secure Cargo Transport

Are you worried about whether the cargo is properly secured? Is it overloaded? Is the cargo shifting or sliding? Are you afraid that the lashings will fail and cause it to fall? Securing cargo for transportation can be a complex task, not only because it complies with mandatory US and Canadian regulations but also because it impacts efficiency and safety. However, in practice, improper cargo securing remains a common problem.

Table of Contents

A truckload can weigh tens of thousands of pounds. If this cargo is not properly secured, it can lead to traffic accidents. According to a study by the American Automobile Association Foundation, falling cargo caused over 200,000 accidents between 2011 and 2014. This article will delve into the critical roles and types of chains and rigging, as well as how to choose the right chains and rigging for your transportation needs.

Cargo Transportation Regulations in the US and Canada

Canadian Regulatory Standards and Compliance

Canada has strict cargo transportation regulations and established national standards that emphasize the importance of vehicle maintenance, driver responsibility, and cargo securing. This is particularly true for different types of rental cargo, including oversized cargo, temperature-sensitive cargo, and hazardous materials. Compliance with these regulations is crucial not only for legal operations but also for safety and protection.

U.S. Cargo Security Laws

U.S. cargo securing laws are overseen by the Federal Motor Carrier Safety Administration (FMCSA). FMCSA regulations cover a wide range of areas, including how to restrain and secure cargo on a vehicle to prevent it from shifting and falling during transportation. These regulations apply to all commercial vehicles carrying cargo operating in interstate commerce. The regulations establish cargo securing standards, requiring all cargo to be properly secured so that it cannot shift on or within the vehicle and adversely affect the vehicle’s stability or maneuverability. Components used in the securing system, including tie-downs, support bars, and anchors, must meet specific performance standards.

Tie-down requirements also specify the number, strength, and location of tie-downs used to secure various types of cargo.

Chain And Binders

Chains and binders, also we called chains and boomers, are integral components of cargo securing systems. They are used to secure heavier cargo to flatbed trailers, ensuring it does not shift or fall during transport. Chains and tie-downs are durable and reliable, making them the preferred choice for heavy-duty applications.

Transport Chains

Grade 70 transport chains, or tie down chains, are used to secure loads to flatbed trucks, preventing them from falling or sliding and ensuring the safety of truck drivers and other road users. The most commonly used type of transport chain for securing loads is grade 70 transport chain, also known as G70. Grade 70 transport chain is approximately 20 times stronger than grade 30 or 43 chains. It is also sometimes used for towing. Overall, tie down chains offer a significantly higher strength-to-weight ratio.

G70 chains are designed specifically for bindering loads and are made of high-strength carbon steel. Grade 70 transport chains are used to secure loads to flatbed trucks. This means they are used solely for bindering loads. Therefore, they are also known as transport chains and load binders. These chains are not only very strong, but their gold color also makes them more visible.

For heavier loads, grade 80 and grade 100 chains can be used. These chains are made of high-strength alloys and are designed for overhead lifting applications, where a dropped load could cause injury or property damage. Of course, the higher the grade, the more expensive the chain. All chains are appropriately stamped with their grade at specific lengths, making it easy to identify the grade of chain you’re using.

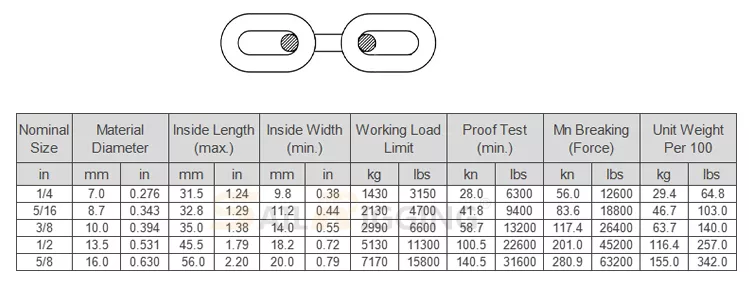

The following table shows the dimensions and working tensions of NACM 96 G70 chains for your reference.

Load Binders

Load binders, also known as chain binder, is a device used to secure a chain around a load. Typically used with a chain, it utilizes the interlocking force between chain links to lock the rigging hook flat against the chain link. By tightening the securing device, it secures the load during transportation, moving, shipping, or storage.

There are two main types of chain binders:

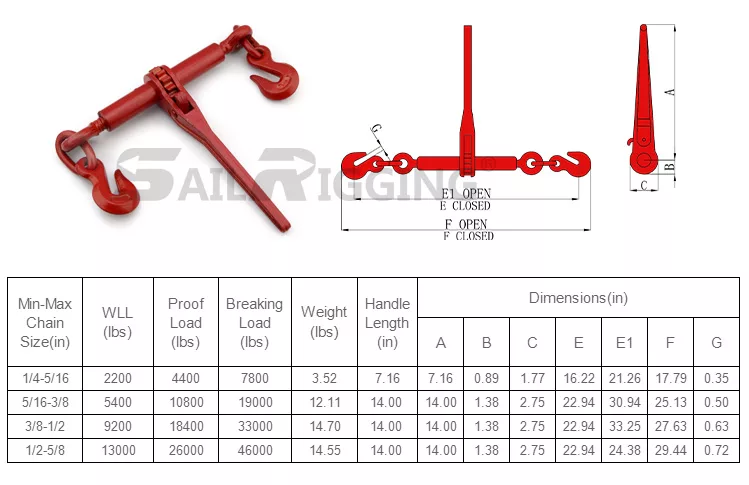

Ratchet Chain Binder: These load binders use a ratchet mechanism to tighten the chain. They have a mechanical advantage, allowing them to exert a high tension with minimal effort. Below is a table of dimensions and working tensions for common American ratchet tie-downs.

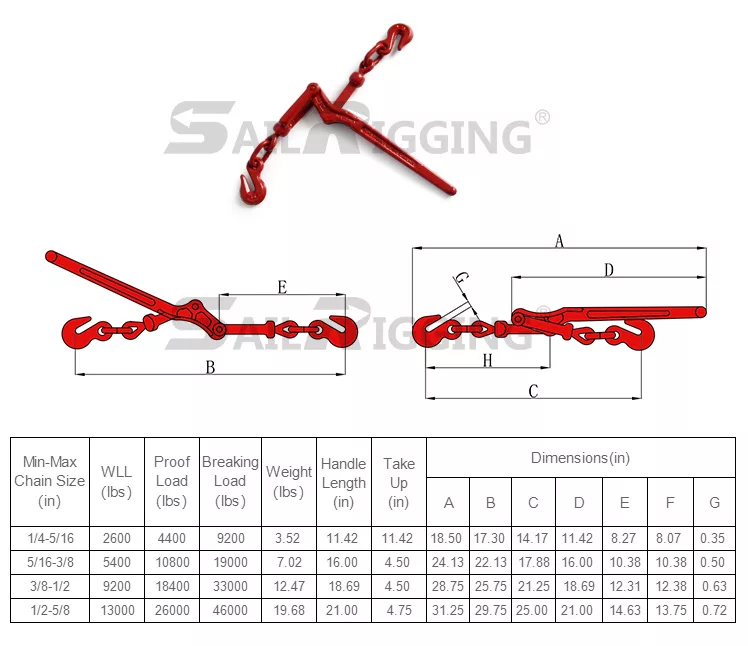

Lever Chain Binder: also known as snap load binder, use leverage to tighten the chain. They operate faster than ratchet chain binder, but require greater force to operate. Below are the dimensions and working forces of common US type chain binder.

In addition to these two common load binders, we also offer recoilless chain load binder, spring chain load binder, and Australian type load binder, European type load binders. For more information on load binders, please contact Qingdao Sail Rigging Co., Ltd.

Choosing the Right Chain and binders

When selecting chain and binder, consider the following factors:

Load Weight: Ensure the cargo weight does not exceed the Working Load Limit (WLL) of the chain and binders.

Cargo Type: Different types of cargo may require different securing methods. Cargo with abrasive or sharp edges may require additional protection to prevent chain damage.

Chain Length and Diameter: The chain should be long enough to securely secure the cargo, and its diameter should match the required Working Load (WLL) of the load. The hook size on the strapping should match the diameter of the chain link. It is best to purchase shipping chain with hooks on both ends.

Compatibility: Chains and strapping come in different grades, indicating their strength and load capacity. Always use chains and strapping of the same grade. Using high-grade strapping with low-grade chain may result in underutilizing the strapping’s load capacity, or worse, chain failure. Avoid using inappropriately sized chains or worn load binder, as these can cause equipment failure or load shifting, impacting vehicle balance and control.

Conclusion

Chains and binders are essential tools in the freight transport industry, especially for flatbed trailer, providing the necessary strength and reliability to secure heavy loads. Understanding the different types of chains and binders, choosing the right cargo control equipments for your needs will prioritize safety and compliance at every stage of freight transport. More information about chain and binder, you could contact Sail Rigging right now.