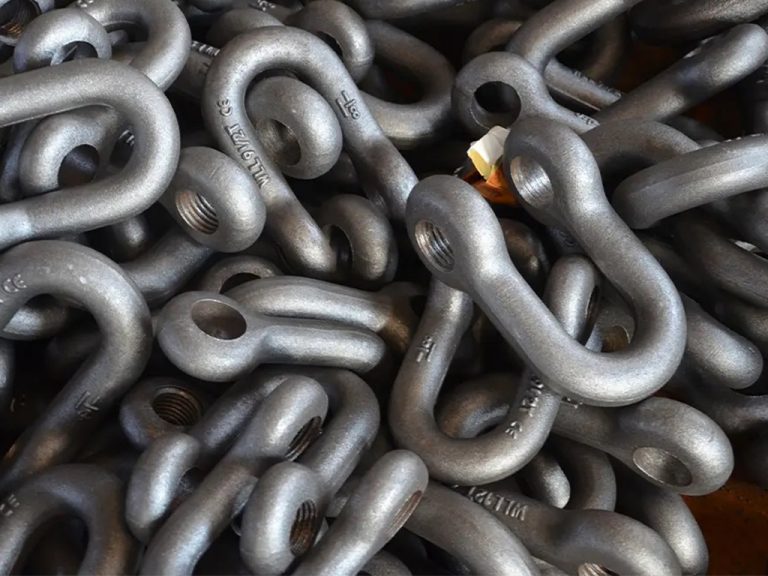

Shackles are an essential component in various industries, including rigging, lifting, and maritime applications. They come in different types, each with its unique design and purpose, but mainly 4 key parts of shackles.

- Bow or D-Ring:

The bow or D-ring is the central and most visible part of the shackle, and its design is a crucial factor in determining the type of shackle. There are two common types: bow shackles and D-ring shackles.

Bow Shackle: Bow shackles have a rounded or U-shaped design, making them suitable for various applications, including those with side-loading. Their curved shape allows them to accommodate a broader range of angles and loads, making them versatile and commonly used in lifting and rigging operations.

D-Ring Shackle: D-ring shackles have a “D” or horseshoe-shaped design, with a straight edge and a curved edge forming the D shape. This design provides increased stability in one direction, making D-ring shackles ideal for applications where the load is predominantly in one plane, such as when attaching a strap or sling.

- Pin:

The pin is a critical component that holds the shackle together and secures the load. It is a removable, threaded bolt that passes through the holes in the bow or D-ring and is then fastened using a nut or other locking mechanism. There are two common types of pins used in shackles:

Screw Pin: Screw pins are threaded through the shackle’s ears or eyes, making them easy to install and remove by hand. They are commonly used when there is frequent assembly and disassembly of the shackle, such as in temporary rigging setups.

Bolt Pin: Bolt pins are secured with a separate nut and are less likely to accidentally come undone, making them suitable for applications where the shackle must remain securely closed for extended periods or where additional security is required.

- Body:

The body of the shackle is the part that connects the bow or D-ring to the pin. It acts as a bridge, ensuring the load is evenly distributed between the bow or D-ring and the pin. The design of the body can vary:

Short Body: Some shackles have a more compact body, which is designed for applications with limited vertical clearance or where the shackle needs to fit into tight spaces. Short bodies are often found in screw pin shackles.

Long Body: Shackles with a longer body offer greater clearance and are suitable for situations where the shackle needs to rotate or pivot freely. These are common in bolt pin shackles.

- Ears or Eyes:

Some shackles, particularly those used in maritime, towing, or heavy-duty applications, may have additional attachment points called ears or eyes. These ears or eyes are extensions of the bow or D-ring and provide a convenient means of attaching ropes, cables, chains, or other rigging equipment.

Ears: Ears are often shaped like flattened extensions on the sides of the bow or D-ring and provide attachment points for hooks, ropes, or other hardware.

Eyes: Eye shackles have a more circular, ring-like extension on the bow or D-ring, providing a versatile attachment point for various connections.

In conclusion, these components and their variations is essential for selecting the right shackle for specific applications and ensuring safe and efficient use in various industries, from construction and manufacturing to maritime and off-road activities. If you want to learn more, feel free to contact Sail Rigging.