What Is An Eye Bolt?

Eye bolts, also known as eye nuts, eye bolts, eye mechinery bolts, etc., are usually used as connection points for rigging, anchoring, pulling, pushing or lifting applications. They are commonly used rigging lifting accessories and fasteners. Not only are they suitable for traditional industries such as ports, electricity, steel, shipbuilding, petrochemicals, mining, railways, etc., they are also widely used in construction and various types of mechanical equipment. It is mainly used to connect slings and other mechanical equipment to achieve the purpose of lifting objects. Therefore, understanding the size, material, process, and use of the eye bolt is crucial for the safe use of eye bolts.

Table of Contents

Parts Of Eye Bolts

Eye bolts are a threaded connector that consists of a screw, a nut, and a lifting eye. The threads on the screw can be matched with the nut to achieve a tightening effect by tightening. The lifting eye can withstand and transmit force. The connection point between the lifting eye and the screw is usually the largest diameter to ensure that they can withstand the maximum force. The following are the terms related to the lifting eye.

Eyebolt – The loop formed at the top, which can be bent, welded or forged

Shoulder – The “skirt” where the eye and shank meet, designed to resist bending

Shank – The threaded shaft that connects to the eyebolt

Always make sure the eyebolt you choose meets or exceeds the working load limit for the task at hand, and is comparable to the working load limit of the sling and other rigging hardware being used.

How Are Eye Bolts Measured?

The best way to understand eyebolts is to look at the size of the eyebolt. This should be done from directly under the eye, as the shank lengths vary. The lengths of different types of eyebolts vary greatly.

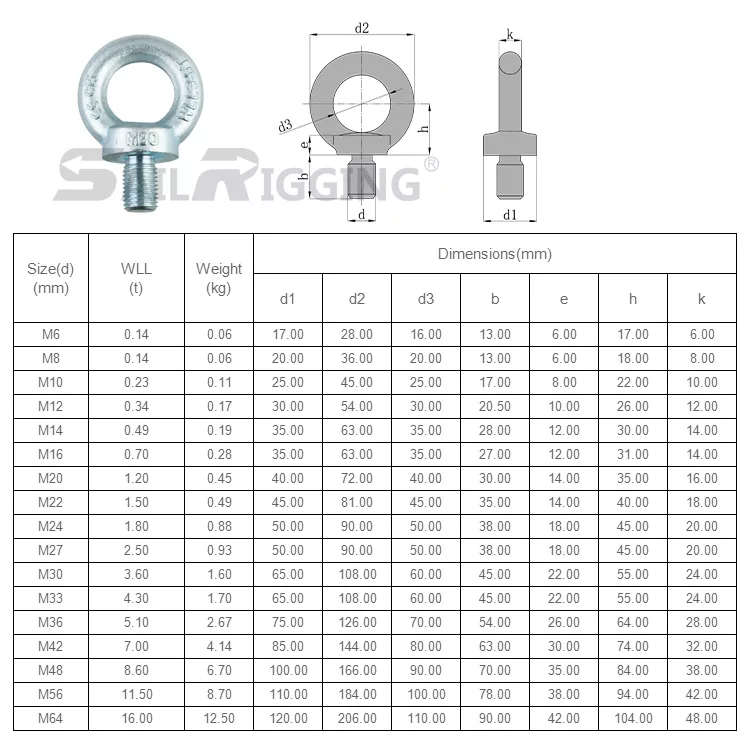

Eyebolt size chart

The best way to understand the size is to use an eyebolt size chart. Below is a common DIN580 size chart that clearly shows the measurement points for the dimensions to ensure the eyebolt is the correct size.

Rod diameter (thread) (d)

Rod length (b)

Bolt rod eye outer diameter (d2)

Bolt rod eye inner diameter (d3)

Bolt rod eye diameter (d2) and rod length (b) are the most important parameters of eye bolts because they affect the working load limit of the bolt and the thickness of the installation material.

How To Produce Eye Bolts?

After integral forging, normalizing and descaling, ensure that the standard hardness value is achieved. Its grade strength is higher and the tensile force is higher. Usually 45# steel, after heat treatment and heating, can reach industrial grade 8.8. If it is alloy steel, after heat treatment, it can reach a higher grade. SAIL RIGGING can provide a tensile test report that meets or even exceeds ASME standards. The maximum working load of the standard DIN580 lifting ring can reach 16T, and we can even customize it according to customer requirements.

Forged lifting ring bolts are hammered or pressed to change the grain structure of the metal to create a stronger, harder and more durable product. Forged lifting rings are not just an ordinary screw, but an engineering product that has undergone strict quality control. Forged lifting rings are suitable for heavy lifting applications because they are stronger than wire lifting ring bolts, can withstand loads up to the tensile strength of their material, and are available in larger sizes.

How To Use Eye Bolts?

1. Select the appropriate specification and model, select the eye bolt according to the rated weight, and avoid exceeding the working tension of the eye bolt.

2. Check the integrity and quality of the thread;

3. Pay attention to the transmission direction, and do not allow the eye to be twisted under the action of lateral force;

4. Do not use spring washers instead of flat washers to ensure uniform and firm tightening force.

Standards Of Eye Bolts

The lifting industry standards also have corresponding regulations on the use of eye bolts, mainly including the following standards:

- CE/EN standard: European standard

- ASME standard: American standard

- JIS standard: Japanese standard

- DIN standard: German standard

Different standards have different regulations on the size, material, load and use conditions of eye bolts. Therefore, when selecting eye bolts, it is necessary to select the appropriate standard and model according to the specific use scenario and requirements.

ISO standards are generally applicable to common lifting needs around the world, while CE/EN standards are applicable to lifting needs in the European market. ASME standards are the standards used by the lifting industry in the United States, while JIS and DIN standards are the standards used in the lifting field in Japan and Germany. At the same time, various standards have different requirements on the quality and safety performance of eye bolts, so it is necessary to select according to the actual situation.

What Are Eye Bolts Used For?

1. Handling, In the field of mechanical manufacturing, such as mold design and production, eyebolts are needed for handling. Eyebolts have excellent load-bearing capacity and can cope with the lifting needs of heavier objects. In construction, they help to lift building materials and components. In the shipbuilding industry, they assist in lifting various components.

2. Loading and unloading, In bridge construction, they can effectively lift various components, saving manpower and time. In power equipment installation, it is convenient to lift large transformers and other equipment. In pineapple point equipment, it can be quickly put into use, assemble equipment, and maintain lifting work. In the petrochemical industry, it helps to lift large pipelines and storage tanks.

3. Lifting, In stage construction, it can withstand vertical tension, lift stage equipment and props, and ensure the stability of lifting. In mining, it assists in lifting ore and mechanical equipment. In automobile manufacturing, it is convenient to lift body and engine parts. In emergency rescue, lift trapped heavy objects or trapped people to assist fire rescue.

4. Anchoring, eye bolt anchors are used in outdoor equipment, fix ropes, swings and other entertainment facilities, in home and gardening, hang objects, etc.

Conclusion

Selecting and using the right eye bolt is critical to a safe and reliable project. Since 2009, Sail Rigging has been helping you select the right eye bolts for lifting and rigging. DIN580, DIN582, JIS1168, JIS1169, G291, G277, G279, G400… no matter which standard eye bolts you need, what material the eye bolt is made of (carbon steel eye bolt, stainless steel eye bolt), the experts at Sail Rigging can guide you and provide quality products. Contact us now.