Ultimate Guide To Wire Rope Thimble : Type, Standards, Sizes, Applications and Installation Methods

Wire rope thimbles and ferrules are essential components for installing wire ropes and are core parts in many heavy-duty applications such as traction, lifting, and hoisting. Today, we’ll talk about wire rope thimbles, which may seem insignificant but are very important. Wire rope thimbles are very practical at the point where heavy objects connect to a loop.

Here, we will provide detailed information on everything you need to know about wire rope thimbles, including what they are and why choosing the right thimble is important for your loop applications, the classification of wire rope thimbles, and how to install them.

Table of Contents

What are Wire Rope Thimbles?

Wire rope thimbles are robust connection points for wire rope assemblies, preventing deformation, protecting the wire rope, and extending its service life. With a wire rope thimble, the thimble protects the wire rope loop, and when the loop is under tension, the load is concentrated at the apex of the loop. The wire rope thimble acts as a buffer, providing necessary structural support. Without a wire rope thimble, stress would accumulate more rapidly at the eye of the rope, making it more susceptible to damage.

Why Use Wire Rope Thimbles?

They play a crucial role in maintaining the strength of the wire rope. The wire rope thimble acts like a protective shield, protecting the wire rope loop. When the loop is under tension, the load is concentrated at the apex of the loop. Without the protection of the thimble, stress would accumulate more rapidly. The thimble acts as a buffer, providing necessary structural support.

• Prevents wear and tear: Thimbles not only prevent wear but also form a barrier, acting as the first line of defense against rope abrasion. This protection is especially important when the rope is subjected to vigorous or continuous movement, ensuring the integrity of the rope remains intact for a longer period.

• Prevents kinking: Wire rope thimbles help maintain the natural shape and alignment of the wire rope. Deformation can lead to kinking, which can lead to breakage. With a thimble, the wire rope loop avoids being flattened at the eye, allowing it to continue functioning optimally and preventing breakage.

Materials of Wire Rope Thimbles

- Carbon Steel Thimbles

Carbon steel thimbles, with a galvanized surface treatment (hot-dip and electroplating), use hot-dip galvanizing, which creates a thicker coating than electroplated zinc thimbles and is more corrosion-resistant.

- Stainless Steel Thimbles

Stainless steel thimbles are available in 314 and 316 grades, offering greater resistance to high temperatures and corrosive environments, especially suitable for marine environments and able to withstand various harsh weather conditions. Heavy-duty stainless steel thimbles feature a heavy-duty design and are ideal for marine vessel applications.

Types of Wire Rope Thimbles

Wire rope thimbles mainly come in two different grades: light-duty and heavy-duty. Light-duty thimbles are suitable for static applications, especially for permanent installations with light loads. Heavy-duty thimbles are suitable for lifting, towing, and applications where users frequently connect and disconnect the thimble from other rigging components. Below are some common types of thimbles.

- US Heavy Duty Thimble G414

This is an American-style heavy-duty wire rope thimble, preventing wear and deformation of the wire rope eye. Compared to standard thimbles, it can withstand higher loads. It is manufactured using a stamping process, with an electroplated or hot-dip galvanized surface treatment. Available sizes range from 1/4 inch to 2-1/4 inches (0.25 inches – 2.25 inches).

- US Light Duty Thimble G411

This is an American-style light-duty wire rope thimble, a standard general-purpose wire rope thimble. It is a light-duty stainless steel thimble suitable for static applications with light loads. It is manufactured using a stamping process, with an electroplated or hot-dip galvanized surface treatment. Available sizes range from 1/4 inch to 2-1/4 inches (0.25 inches – 2.25 inches).

- Light Duty Thimble DIN6899A

This is a German-style light-duty wire rope thimble, a small stamped wire rope thimble, conforming to the DIN6899A standard. Manufactured using a stamping process, with a common electro-galvanized surface, it is more suitable for light-duty applications and offers good strength and durability. It is commonly used for general lifting, fixing, and anchoring purposes, with available sizes ranging from 3mm to 28mm.

- Heavy Duty Thimble DIN6899B

This is a German-style heavy-duty wire rope thimble, conforming to the DIN6899B standard. It is manufactured using a stamping process, with electro-galvanized or hot-dip galvanized surface treatment. Available sizes range from 2.5*3mm to 97*100mm, suitable for heavy-duty applications, especially lifting, towing, and applications requiring frequent connection and disconnection of the thimble with other rigging components.

- DIN3091 Thimble

This is a German-style heavy-duty wire rope thimble, conforming to the DIN3091 standard (specifically designed for wire rope end connections). This heavy-duty solid thimble features a one-piece structure, offering extremely high strength and load-bearing capacity. The surface is either natural or electro-galvanized, with available sizes ranging from 8-80 mm.

- European Type Thimble

This is a commonly used European-style thimble, manufactured using a stamping process, with electro-galvanized or hot-dip galvanized surface treatment. Available sizes range from 3mm to 32mm.

- BS464 Thimble

This is a commonly used British wire rope thimble, conforming to the British standard BS464. The surface is electro-galvanized or hot-dip galvanized, with available sizes from 5mm to 76mm, typically suitable for light to medium load applications.

How to Install a Wire Rope Thimble

Thimbles can be used with cables and ropes to form rigging components. During use, it is crucial to ensure that the thimble is the correct size and securely fixed in the eye of the cable being used. If the thimble is too loose in the eye, it may come loose or rotate; if it is too small or too large, it will be difficult to connect to other appropriately sized rigging accessories. Therefore, correct installation of the wire rope thimble is essential.

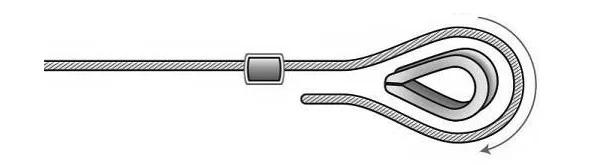

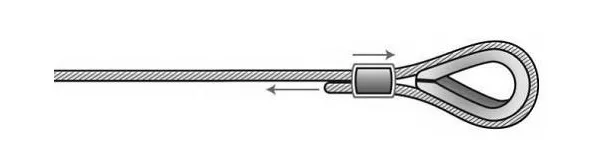

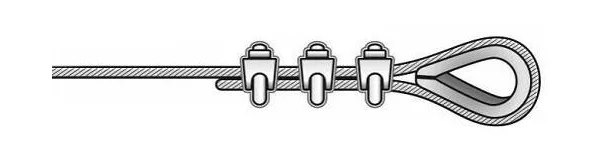

Step 1: Simply thread the end of the wire rope through the thimble and then wrap the end of the wire rope around the outer groove of the thimble.

Step 2: Thread the end back through the thimble and pull the end tight so that it fits snugly around the thimble.

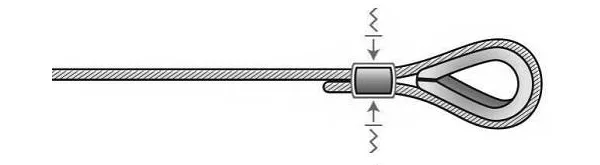

Step 3: Once in place, we recommend using a crimping/swaging tool to securely crimp the sleeve onto the rope to firmly secure the thimble loop.

After installation, we recommend load testing the wire rope assembly with a load equal to or greater than the expected load to ensure your loop/eye will operate safely.

Conclusion

Wire rope thimbles provide a strong connection point for wire rope assemblies, preventing deformation and extending service life. Using a thimble is strongly recommended when attaching fittings to wire rope assemblies. Sail Rigging offers a variety of wire rope thimbles to meet your needs. If you would like to know more about wire rope thimbles, please feel free to contact Sail Rigging.