Focus On Load Securement To Keep Everyone Safe On The Road

When you are driving on the highway,there is a semi-trailer truck towing a flatbed truck full of cargo next to you, are you worried about whether the cargo on the truck is safe? Will it fall off? How can this truck not fall off? What exactly keeps the cargo in place. After all, road safety is related to us personally.

In 2021, the Federal Motor Carrier Safety Administration (FMCSA) reported that there were 180,316 traffic accidents involving large trucks and buses, 5,414 deaths, and 89,313 injuries. In 2021 alone, a total of 1,368,270 inspections of large trucks and buses were carried out, 4,976 serious/acute violations were found, and 30,543 non-serious/acute violations were found. Therefore, it is crucial to equip your cargo with the correct and sufficient tie-down equipment.

Cargo Securement is particularly important in places such as the United States, Canada, and Australia. Now let’s break down the basics of flatbed cargo fixing to help you learn more about cargo control knowledge.

Table of Contents

Regulations Of Cargo Securement In US

In the United States, there are several federal regulations that set out commercial motor vehicle load security requirements to ensure safe travel. Federal Motor Carrier Safety Administration (FMCSA) regulations Section 392.9 states that commercial vehicle drivers must inspect and properly secure all cargo before starting and operating the vehicle.

In addition, drivers must:

- Inspect cargo within the first fifty miles of a route/trip to ensure nothing has moved or is loose;

- Inspect cargo within the first fifty miles of a route/trip to ensure nothing has moved or is loose;

- Re-inspect cargo when changing duty; or the vehicle has been in operation for three hours; or has traveled 150 miles; whichever occurs first.

An unofficial rule regarding cargo security is that the driver is the owner of their vehicle and is ultimately responsible for their own safety and the safety of those around them. Federal Motor Carrier Safety Administration (FMCSA) regulations Sections 393.100-393.136 detail the types of tie-downs allowed and the minimum requirements, as well as the rules for securing cargo such as pipes, steel, heavy equipment, etc.

Failure to comply with Federal Motor Carrier Safety Administration (FMCSA) and Department of Transportation (DOT) regulations can have high consequences as a large number of accidents can occur, resulting in high costs for operators and companies. Proper cargo securing and training is essential for all drivers who operate vehicles on the road.

Basics of Cargo Securement

Make sure the equipment used to tie down and secure cargo is properly rated. These ratings will tell you its overall strength, breaking strength, and working load limit (WLL).

According to Federal Motor Carrier Safety Administration (FMCSA), the weight of the equipment used to secure cargo must be at least half the weight of the cargo. Depending on the cargo weight limit, make sure to use an adequate number of tie-down equipment.

Common Cargo Securement Equipment

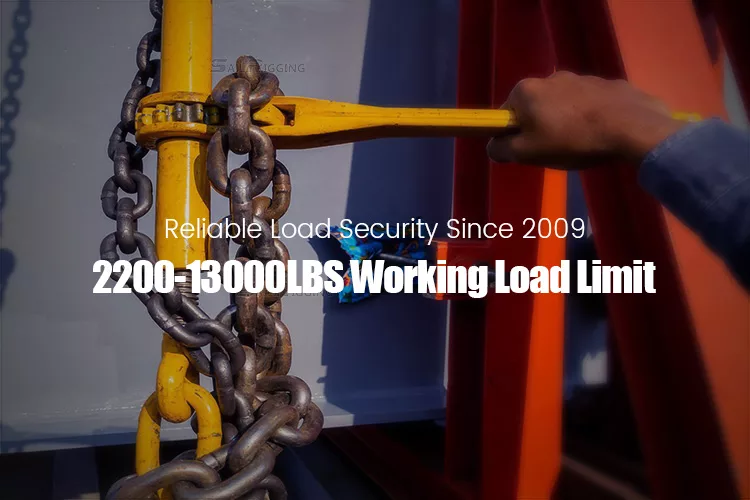

Chains and binders are essential securing tools in the transportation industry, especially for heavy equipment such as tractors, planters, and steel hot coils. When securing industrial equipment, agricultural machinery, construction materials, and oversized loads, it is difficult to secure cargo in place without chain load ties.

Chain binder

also known as load binder, used with transport chains, are devices used to tighten chains when securing cargo during transport. With chain binders, chains around the load can be tightened and secured to prevent it from shifting or falling during transport. Common chain binders include ratchet load binder and lever load binder. If you want to know the difference between ratchet type chain binder and lever type chain binders, you can refer to What Is A Chain Binder And How To Use A Chain Binder .

Chains

also classed in different grades, each designed for specific weights and load types. Grade 70 transport chains, often referred to as “transport chains,” are the preferred choice for flatbed trucks and heavy cargo. Grade 80 and 100 transport chains are designed to carry heavier loads and are used in industrial or construction applications where the heaviest loads need to be secured. Grade 43 safety chains, used as trailer chains, are reinforced transport chains that are not easily cut, providing additional protection for expensive or sensitive cargo.

Factors To Consider When Choosing Cargo Securement

- Load weight: The weight of the cargo will determine the grade and size of the chain. Always make sure the chain’s working load limit matches or exceeds the load weight.

- Cargo type: The type of cargo being transported will influence your choice of tie-downs and chains. For example, fragile cargo or finished products may require gentler handling and extra protection, while heavy machinery will require sturdier chains and tie-downs.

- Environment: If your cargo will be exposed to harsh environments such as rain, snow or salt water, choose corrosion-resistant chains to prevent rust and damage.

Suggestions for Cargo Securement

- Regularly check all chains and rigging for general damage and wear;

- It is strongly recommended that you use at least two chains, even if one is enough to secure the cargo (when applicable) you could refer to this How Many Chains And Binders For A Flatbed ;

- All cargo and dunnage must be securely tied, secured and balanced on the flatbed trailer;

- If the trailer is closed, this does not ensure that the cargo inside is always secure, and additional securing and safety measures are always important and recommended;

- Road vibrations and wind can cause the tie-downs to loosen. Therefore, it is necessary to check safety thoroughly throughout the journey;

- If the height of the cargo is higher than the vehicle, additional securing measures are required to ensure safety against wind resistance and ensure that the route complies with height restrictions.

Common Load Safety Violations

- Lack of sufficient number of chains and binders;

- Use of damaged chains and binders;

- Failure to secure cargo and dunnage;

- Use of loose or inappropriate chains and binders;

Conclusion

Therefore, choosing appropriate and sufficient cargo control equipment, regularly inspecting cargo securement equipment and keeping the securing methods in optimal working condition are essential to ensure the safety of cargo and everyone on the road. If you want to know more about cargo tie-down and securing safety, you can consult us.