What Is A Safety Chain?

A safety chain is a flexible tension device usually connected between the towed vehicle and the towing vehicle and normally has sufficient strength to prevent separation of those vehicles if the primary coupling device fails.

Table of Contents

Where To Use A Safety Chain?

A Safety Chain is widely used in towing, marine and recreational vehicles (RVs), which are especially important for load security. They reduce the risk of detachment and enhancing overall safety during transportation.

- Safety Chains For Towing

Standard Towing Chains: Used in light-duty towing applications, such as securing small trailers to vehicles. These chains offer a backup connection to prevent the trailer from detaching if the primary hitch fails.

Heavy-Duty Towing Chains: Designed for larger trailers or vehicles, heavy-duty chains are used in commercial and industrial towing applications where stronger chains are needed to secure larger loads.

- Safety Chains In Marine

Boat Docking Chains: Used to secure boats to docks or moorings. These chains act as a secondary connection in case the primary mooring line or rope fails, ensuring that the boat remains safely in place.

Anchoring Safety Chains: Used in marine anchoring systems, safety chains provide extra security to ensure that vessels remain securely anchored, especially in rough or turbulent waters.

- Safety Chains For RV Trailers

Recreational Vehicle Chains: Safety chains are used to secure RVs, trailers, or caravans to towing vehicles, ensuring that the load remains connected during travel. These chains are crucial for preventing detachment and accidents, especially when traveling on highways. These chains prevent the trailer from becoming unhitched from the towing vehicle. They act as an additional fail-safe connection when towing trailers of any size.

What Is The Material Of A Safety Chain?

Safety chains must be constructed from durable, high-strength materials to ensure they can handle significant loads and stand up to environmental conditions. The choice of material and surface treatment depends on the specific application.

- Carbon Steel: Carbon steel chains are commonly used for standard towing and transport applications. They are cost-effective and offer adequate strength for everyday use.

- Alloy Steel: Alloy steel chains are stronger and used in heavy-duty applications where greater strength is required, such as commercial towing or marine applications.

What Is The Surface Treatment Of A Safety Chain?

- Self-Color with Oil: These chains have a natural, untreated finish with a protective oil coating to prevent rust during storage. They are often used for non-exposed, indoor applications.

- Galvanized: Galvanizing provides a protective zinc coating that helps prevent rust, making these chains ideal for use in outdoor and marine environments.

- Powder Coating: This finish provides additional protection against corrosion and wear, especially for heavy-duty towing chains exposed to harsh conditions.

- Stainless Steel Finish: Stainless steel safety chains typically have a polished finish, ensuring long-lasting durability and a resistance to corrosion, especially in marine environments.

Different Chain Hook Assemblies

Safety chains can be used as a redundant securing system or as a primary tie-down device. The U.S. Department of Transportation (DOT) requires the use of safety chains for most vehicle and equipment towing. If your primary tie-down device fails, the safety chain will take over. Sail Rigging offers chains from Grade 43 to Grade 70, with load capacities ranging from 2,000 to 24,000 pounds to meet your application and workload requirements. Chain and hook combinations vary depending on the application scenario. Common chain and hook combinations include the following:

| Type | Picture |

| G30 Chain and Trailer S-Hook with Latch on Two Ends |  |

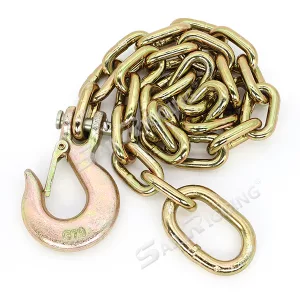

| G43 Chain and Clevis Slip Hook with latch on One End |

|

| G43 Chain and Clevis Slip Hook With Latch On Two Ends |  |

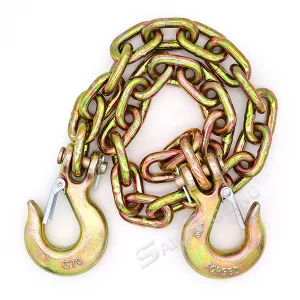

| G70 Chain And Clevis Slip Hooks With Latch On Two Ends |  |

FAQ

1. Are safety chains required on trailers?

Yes, many types of trailers are required by law to be equipped with safety chains to prevent the trailer from separating from the towing vehicle in the event of a hitch failure. Specific requirements vary by state, but generally, a trailer must be equipped with at least two safety chains.

2. How to attach safety chains to a trailer?

① Inspect the chains to ensure that the links are intact and that nothing is loose or damaged.

② Inspect your hitch carefully. Depending on your trailer configuration, you may have an S-hook, a sliding hitch, or a grab hitch.

③ Inspect the connection between the safety chain and the trailer’s drawbar. If it’s welded, inspect the weld for cracks or damage.

④ Once everything is in working order, cross the chains and attach them to the trailer’s hitch in an X-shaped arrangement.

3. Why do people cross trailer safety chains?

Cross the trailer safety chains, forming an “X” shape or bracket underneath the tow hitch. This will prop up the trailer’s drawbar and prevent the trailer from hitting the ground if the main hitch separates from the towing vehicle. This prevents the hook from digging into the road, preventing the trailer from tipping over, and gives the driver time to slow down and stop safely.

Conclusion

Safety chains play a vital role in ensuring the security of trailers, RVs, boats, and other vehicles during transit. It’s very important to know what is a safety chain and how to choose safety chain. If you don’t know how to choose safety chain, please don’t hesitate to contact Sail Rigging.