Understand WLL MBL Of Turnbuckles

A turnbuckle is a common rigging device used to adjust tension and reduce slack in ropes, cables, or similar tensioning components. It has a right-hand thread on one end and a left-hand thread on the other. It’s commonly used to secure structural components such as bridges and buildings, stabilize power lines, shade sails, tents, and more.

Table of Contents

When it comes to turnbuckles, we often receive questions like, “What’s the working load limit of a 3/8-inch turnbuckle?” “What’s the normal operating tensile strength of a 1/2-inch turnbuckle?” “What’s the minimum breaking force?” “What’s the safety factor?” “Which turnbuckle is most popular in Europe?” “What turnbuckle finishes do European customers often purchase?” Lifting operations often involve a variety of technical terms, such as WLL, SWL, and MBL. Understanding their meaning is crucial for selecting the right lifting equipment. This article will provide a detailed explanation of these terms and explain their specifications for several popular turnbuckles. We hope this will be helpful in choosing a suitable turnbuckle.

Understand the WLL (Working Load Limit) Of A Turnbuckle

WLL is a commonly used abbreviation in lifting operations. It refers to the maximum load a turnbuckle should be able to withstand. It stands for Working Load Limit and is established by the turnbuckle manufacturer. This means it is the maximum load a non-stationary lifting device is designed to withstand under the conditions specified by the manufacturer, ensuring that the load is evenly applied to the turnbuckle and that side loads are avoided. This value is based on typical environmental conditions; special circumstances, such as extremely high or low temperatures, chemical solutions or vapors, and prolonged immersion in salt water, must be considered. Never exceed the Working Load Limit.

Understand the SWL (Safe Working Load) Of A Turnbuckle

This abbreviation stands for Safe Working Load. SWL was previously a common term, but the legal meaning of the word “safe” has largely replaced it with WLL. Generally speaking, today’s Safe Working Load corresponds to the WLL of all lifting equipment below the crane hook, such as hooks, shackles, and other lifting equipment. The term “capacity” is used for cranes, hoists, and winches. It is usually affected by the weight of the lifting beam or lifting equipment assembled below the crane hook.

The term “safe working load” may still be used to refer to a reduced load based on the specific circumstances of the use environment. A qualified person must always conduct a risk assessment before lifting to determine whether the load capacity may be affected.

Understand Proof Test Load (Proof Load) Of A Turnbuckle

“Proof testing” refers to a quality control test performed on a product for the sole purpose of detecting material or manufacturing defects. The proof test load (usually twice the working load limit) is the load that the product can withstand without deformation in its new state under laboratory testing conditions. A continuously increasing force is applied to the product in a straight line at a uniform speed on a standard tensile testing machine. The proof test load does not necessarily mean that the product must exceed the working load limit.

Understand MBL/MBF (Minimum Breaking Load/Minimum Breaking Force) Of A Turnbuckle

“Minimum Breaking Load/Force” refers to the load or force that the lifting equipment must withstand before there is a risk of breaking or a change that causes the load to loosen. The minimum breaking strength is the force required to perform a tear test. Load is measured in kilograms/tons, and power is measured in kilonewtons (kN).

The meaning of the safety factor (SF) is the ratio between the load limit (WLL) and the maximum load (MBL), which indicates the strength of the equipment relative to its designed lifting capacity. Standards for each lifting range specify a safety factor, typically ranging from 4:1 to 7:1. Therefore, the maximum load can be calculated as WLL = MBL / SF.

The meaning of the proof load is the load applied to the product by the manufacturer during the proof load test. The load the product should withstand is specified in the current standard.

Remember! When assembling multiple lifting components in a lifting system, it is important to remember that the component with the lowest maximum load determines the WLL of the entire lifting system. When the lifting component consists of multiple components or other lifting structures, the maximum load is calculated using a specified factor.

Popular turnbuckles

Like other rigging hardware products, turnbuckles are available in many different sizes, configurations, and types. Today i will introduce two different types of turnbuckle, US Type drop forged turnbuckle( open-body) and Australian type closed body turnbuckle. These two types of turnbuckles have different working tensions.

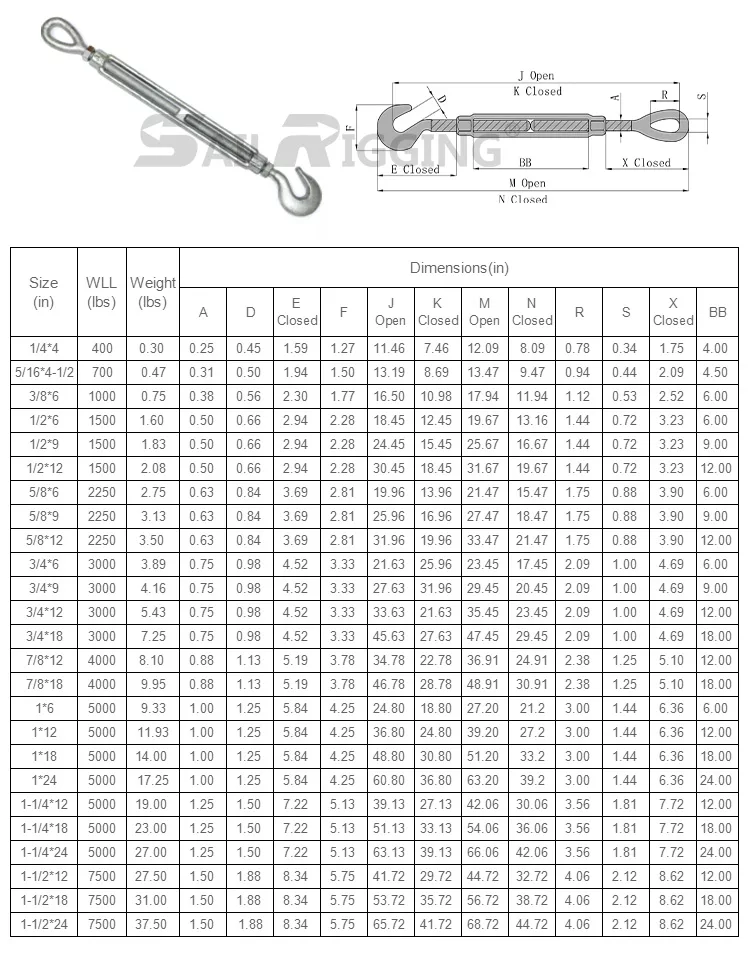

1. US type drop forged turnbuckle

US type drop forged turnbuckles comply with ASTM F-1145. The surface is hot dip galvanized, made from carbon steel. Based on the turnbuckle wire diameter, American turnbuckles use imperial wire. Working load limit ranges from 400-7500 lbs. Generally, eye and eye, eye and jaw, and jaw-jaw turnbuckles are stronger than hook and hook turnbuckles, eye and hook turnbuckles. Their breaking strength is five times the working strength. Taking eye and hook turnbuckle as an example, the following is a table of dimensions and parameters for US drop forged eye and hook turnbuckles.

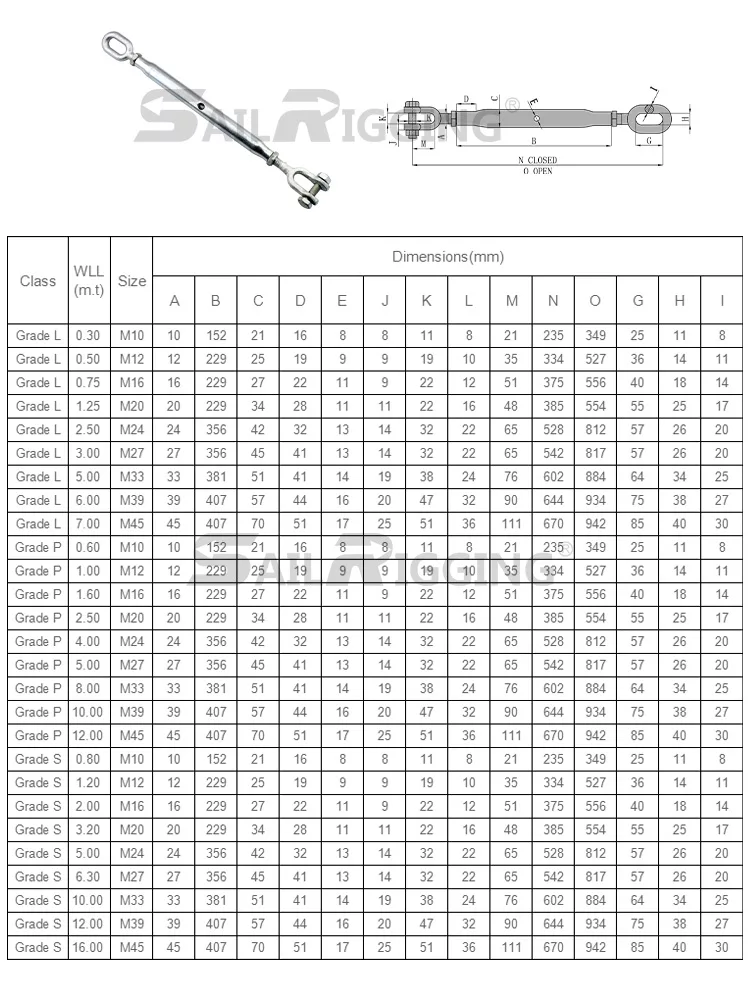

2. Australian type closed body turnbuckle

Australian type closed body turnbuckles comply with the AS2319 standard. Electro galvanized surface, made from carbon steel. Common end types include loop, loop-fork, and fork-fork. Based on the turnbuckle wire diameter, Australian turnbuckles use metric wire. Turnbuckles are categorized as Grades L, P, and S, with working tensile strengths ranging from 0.3 to 16 mt. The following is a table of dimensions and parameters for Australian closed turnbuckles.

>>>Australian type closed body turnbuckle

We hope this understanding of these terms will help you choose a turnbuckle. If you have any questions, please feel free to contact Sail Rigging. Our professional product managers, with extensive industry experience, are available to answer any questions.