A Guideline To Rigging Hooks

When lifting heavy objects, you often use cargo hooks. The right rigging hook is crucial for safe and efficient lifting operations.

But do you know what rigging hooks are? What are the common types of rigging hooks? What are their suitable applications? What is their working tension? What are their sizes? What are their ratings? At Sail Rigging, we offer a wide variety of lifting slings, rigging hardware, wire ropes, hooks, cargo tie-downs, and more. Today, we’ll share some information about rigging hooks to help you choose the right one for safe and efficient material handling.

Table of Contents

What is a rigging hook?

Rigging hooks, also known as cargo hooks, lifting hooks, and sling hooks, are crucial connectors in lifting and rigging operations. They securely attach loads to equipment like cranes and hoists, ensuring safe and efficient material handling.

Types of Rigging Hooks

There are two main ways to connect a lifting hook or sling hook to a sling: a hook with an eye on the top, or a hook with a clevis (also called a clevis) on the top. Some hooks also have a rotatable bearing or bushing on the top. Common rigging hooks include the following:

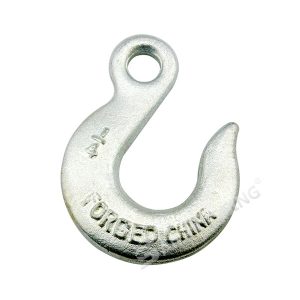

- Eye Hook: This hook features a sturdy eye on the top, making it easy to attach to chains or lifting components. Suitable for general lifting in various industries. There’re 2 types of eye hook,

US type eye grab hook H323/A323 and eye slip hook H324/A324

2. U-Hook (Clevis Hook): This hook features a U-shaped connection point and a pin for quick connection and disconnection. It’s ideal for applications requiring quick connection and disconnection. such as US Type Clevis Slip Hook H331/A331, US Type Clevis Grab Hook H330/A330

3. Swivel Hook: A swivel hook with a bearing or detent allows 360-degree rotation even under load, preventing rope twist and enabling more precise load positioning. Widely used in construction, manufacturing, and other fields. The left is American Swivel Hook S322

4. Grab Hook: Features a narrow throat that “grabs” the chain link, preventing it from slipping off the hook. It is commonly used for tying, shortening, or securing the end of a transport chain. The throat design allows the chain to easily and securely engage between the links, enabling quick and slip-resistant handling. Adjust the load length of the chain sling. We have US type eye grab hook H323/A323 and US type grab hook A330/H330.

- Slip Hook: Similar to a U-shaped hook, this hook has a wider neck and throat than a grapple hook. Sometimes called a sling hook because of its wider neck, it allows a sling to slide through. It is used to adjust the length of a lifting chain or sling. Slip hooks are typically equipped with a safety catch to secure the object being lifted. We have US type clevis slip hook H324/A324, US type clevis slip hook H331/A331

- Self-Locking Hook: The catch automatically locks under load, preventing the hook from accidentally opening under heavy loads, providing additional safety for critical lifting operations.

Rigging Hook Grades

Different grades represent varying strengths and are suitable for different applications. Common rigging hook grades include 30, 43, 70, and 100.

Grade 30, 43, and 70 rigging hooks are typically used for securing loads and lashing cargo. However, they are not suitable for overhead lifting. In real-world situations, some people misuse these lower-grade hooks for lifting tasks not designed for them, which can cause problems. This can be extremely dangerous.

Grade 80 and 100 rigging hooks are made of alloy steel and are the grades required for overhead lifting applications to safely handle heavy loads. Grade 80 cargo hooks, also known as sling hooks or lifting hooks, have long been a reliable standard for overhead lifting in many industries. Grade 100 cargo hooks have a working load limit (WLL) approximately 25% higher than grade 80 hooks of the same size. This means you can use a relatively lightweight hook to lift heavier loads.

Rigging Hook Materials

We typically offer carbon steel, alloy steel, and stainless steel hooks for lifting applications. Carbon steel hooks are suitable for non-overhead lifting applications, such as hauling, pulling, or securing loads, while alloy steel hooks are used for overhead lifting. Stainless steel hooks offer better corrosion resistance to seawater, chemicals, and acids, making them particularly suitable for use in marine environments. For more information on rigging accessory materials, please refer to this article.

Working Load Limit

Sometimes also called the safe working load, or W.L.L. or SWL for short, it represents the maximum rated load applied to an object. Therefore, the working load limit of a hook should never be exceeded or cause shock loads to the chain or attachments.

Minimum Breaking Strength

The minimum breaking strength is the minimum tensile force required to break the hook. Dividing this by the safety factor (SF = MBL / WLL) gives the working load limit. Typically, carbon steel hooks have a safety factor of 5:1, while alloy steel hooks have a safety factor of 4:1.

Conclusion

Choosing the right rigging hook depends on a variety of factors, including the load, lifting environment, and safety requirements. When you need to lift large, oddly shaped components prone to rotation, a swivel hook is the optimal solution. When you need to bundle cargo for transport, especially when used with tight rigging, a grapple hook is the best choice. When you need to assist with trailer safety and connection, a clevis hook with a tongue is the perfect choice. If you’re still unsure which type of hook is right for your application, please contact Sail Rigging and we’ll answer any questions you may have about hook types.