The Ultimate Guide To US Type Drop Forged Turnbuckle Jaw And Jaw

Are you struggling with loose cables or rods? Worried about the strength of your rigging connections? Today, we’ll introduce a turnbuckle—the American-style swaged fork turnbuckle—that provides a sturdy and adjustable solution for your tensioning needs.

Table of Contents

What is an US Type Drop Forged Jaw And Jaw turnbuckle?

US type drop forged jaw jaw turnbuckle is a common type of turnbuckle. They consist of two bolts, one with a left-hand thread and the other with a right-hand thread, screwed into each end of a metal body. This mechanical screw mechanism adjusts the tension or length of a rope, cable, or tie rod, creating a secure, pinned connection.

Basic Characteristics of US Type Drop Forged Jaw Jaw Turnbuckles

American-style swaged fork turnbuckles typically conform to ASTM F1145-92. They are made of high-strength 45-gauge steel, drop-forged at high temperatures, and hot-dip galvanized. They offer a breaking strength of five times the working strength and an open-body design.

Parts Of US Type Drop Forged Jaw Jaw Turnbuckle

Body: The metal frame at the center of the device connects to the two threaded end fittings. This is the central part of a turnbuckle, cylindrical or oval in shape. It has both right-hand and left-hand internal threads, also known as reverse threads. The forged body is extremely strong due to the heat, weight, and pressure used in its manufacturing process.

End fittings: These are end fittings that screw into the turnbuckle body. One end has right-hand threads, the other has left-hand threads. They are used to connect to cables, ropes, or other tensioning systems. One bolt rotates clockwise, while the other rotates counterclockwise. This allows the metal housing to rotate in one direction, increasing or decreasing tension. Turning the turnbuckle clockwise pulls the two bolts closer together, increasing tension. Turning it clockwise pulls the bolts apart, decreasing tension. This simple mechanism makes it easy to control the tension of ropes, cables, and chains with virtually no effort.

Three common types of end fittings exist: hook end, jaw end, and eye end, which can be installed at either end of the turnbuckle in any combination.

Hook end – Hook end fittings are used for temporary connections because they are easy to connect and disconnect quickly. Never use in connections where tension could be accidentally released.

Jaw End – Jaw-end fittings consist of jaws and a bolt, secured together with a nut or pin. They are used to connect components that cannot be opened, such as eyebolts.

Eye End – An eye-end fitting is a closed ring that can be attached to a shackle or quick-connect ring.

Take-up length: This is the total length the end fitting can be screwed in and out of the body to “absorb” tension. Drawn Length can be measured based on the “open” or “closed” state of the end fitting: fully extended or fully retracted.

Nut: Also known as a locknut, a nut fits over the threads of the end fitting and tightens against the turnbuckle body to prevent the device from loosening or unscrewing.

US Type Drop Forged Turnbuckle Manufacturing Process

Forged turnbuckles get their name from the manufacturing process. The process of manufacturing a die-forged turnbuckle begins by cutting the metal to the desired size. It is then heated to a red-hot temperature to prepare for the first step of forming. In some cases, the heated metal is directly fed into a die, where pressure and weight form the initial shape. In other cases, initial shaping is done by hand before the workpiece enters the die. Finishing the finished product requires placing it through a series of dies until the desired shape is achieved. Drop forging not only shapes the workpiece but also strengthens its molecular structure.

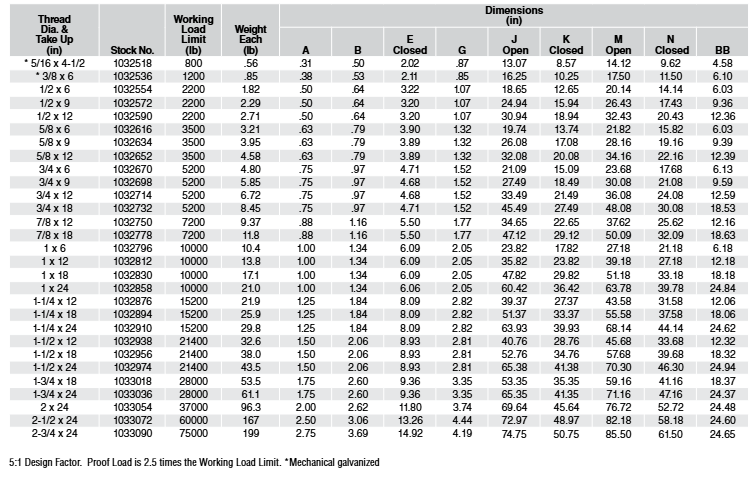

Crosby Jaw & Jaw Turnbuckle HG-228

Hot-dip galvanized finish, end fittings are quenched and tempered or normalized, and the body is normalized heat treated. The forged jaw ends are compatible with bolts and nuts (1/4 inch to 5/8 inch), as well as pins and cotter pins (3/4 inch to 2 3/4 inch). The body features UNC threads and meets or exceeds all ASME B30.26 requirements, including marking, ductility, design factor, proof load and temperature requirements, and other key performance requirements, including fatigue life, impact resistance, and material traceability.

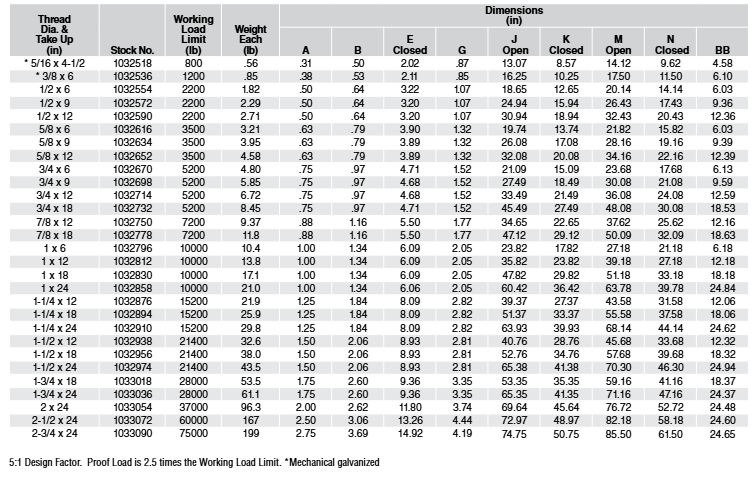

Green Pin Jaw & Jaw Turnbuckle G6313

Hot-dip galvanized finish, drop-forged high-strength steel SAE 1035 or 1045, 5:1 design factor, open turnbuckle design, in accordance with ASTM F1145-92. Both ends are forked joints with pins and cotter pins.

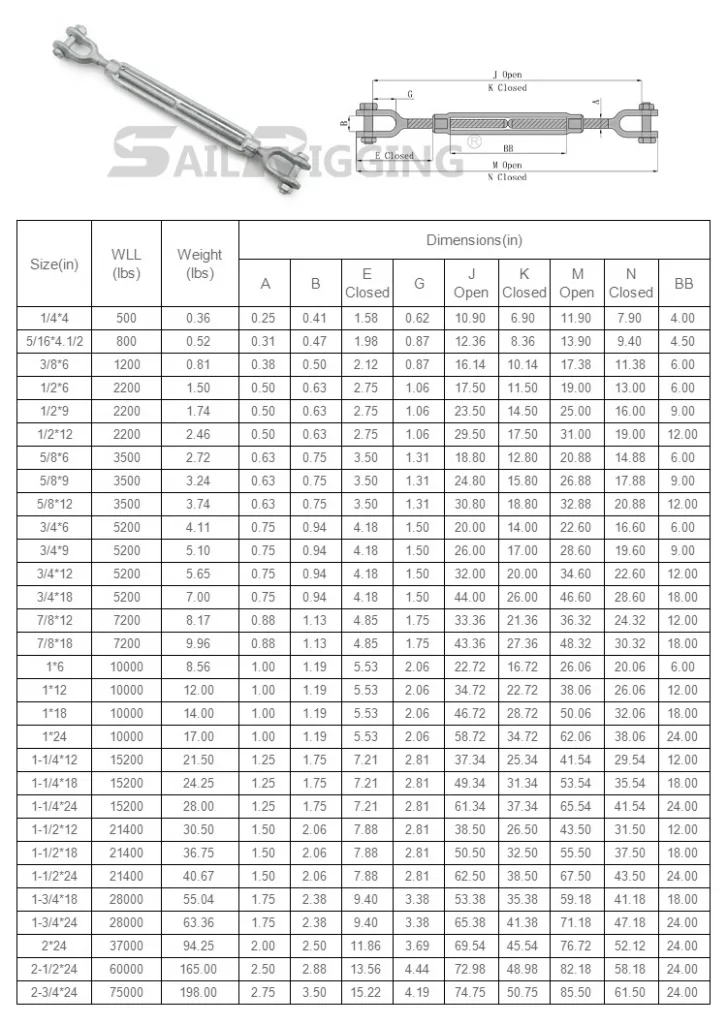

Sail Rigging Drop Forged Jaw Jaw Turnbuckles

The implementation standard is American standard, the material is 45# steel, produced by drop forged process, the surface is hot-dip galvanized, the breaking tensile force is 5 times the working tensile force, and the working tensile force ranges from 500lbs to 75,000lbs.

There’re a wide variety of turnbuckles, not only US type drop forged turnbuckle, but also JIS Type turnbuckle, DIN1480 turnbuckle, DIN1478 turnbuckle. All of these turnbuckles can be used for both simple and complex applications, such as suspension cable construction. If you have more information about US Type drop forged jaw and jaw turnbuckles, please contact our product manager.

More Question You May be Interested

1. Do turnbuckles need jam nuts?

It depends. Some turnbuckles may also be equipped with lock jam nuts to prevent loosening. These can be used in non-critical applications, but are not recommended for critical applications as they put extra strain on the threads.

2. What size turnbuckle tensioner do I need?

There are two sizes you need concern, the thread diameter and the take-up or body length. The thread diameter is directly correlated with the working load limit – the stronger you want your turnbuckle to be, the greater the diameter you should choose.

3. How strong is a 3/8 turnbuckle?